Re: 1958 14' Fleetform

You don't have to angle the stringers to match the angle of the hull. But that's because you do not want them to actually be in contact w/ the hull as you have drawn the stringer above. You need to leave a 1/4" gap between the bottom of your stringer & the hull, this area is filled w/ PB which beds the stringer to the hull. You'll need to use a cove fillet of PB along both sides of the stringer, this gives you a nice gentle curve for the fiberglass to roll from the hull up on to & over the stringers.

A metal spoon from the dollar store, NOT from the kitchen, dipped in acetone makes a nice smooth, rounded fillet.

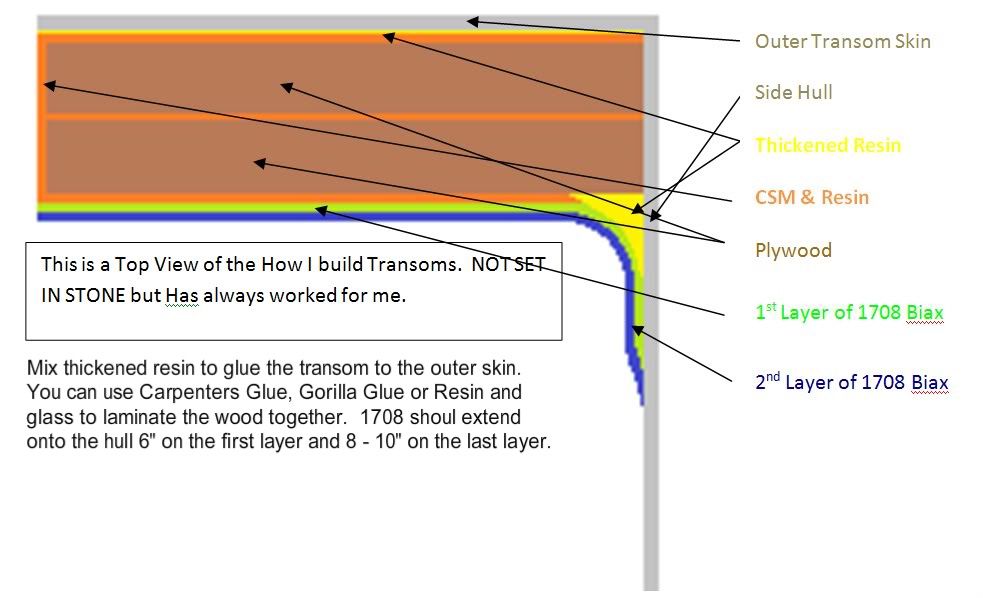

For the transom, you'll want to cut 2 pieces of 3/4" exterior grade plywood (auraco if you can find it, pressure treated is not necessary or preferred) to fit your boats transom skin, on the inside, and leave a 1/4" gap at the bottom up off the hull.

Once you get the plywood (for transom & stringers you probably need 2 full 4X8 sheets) to the house, we can go over the details of how to handle it after you cut it to shape. You will want access to several gallons (5 minimum) of polyester resin, and several yards of CSM & 1708 before you start. There are other materials you will need once you start fabricating the plywood but just the plywood & a gallon of TiteBond3 (to get a gallon you may need to order it) will get you started.

Have you looked in to where you will get the fiberglass materials & polyester resin? Local would be great, but it will be lower quality resin & more expensive to use the polyester resin from HD or Lowes. And it has wax in it. Every time you allow the resin to cure, you would have to thoroughly wash everything down w/ soap & water, dry it & sand it to get the next layer to adhere properly.

Refresh my memory, do the stringers stand up similar to how you have them drawn? Weren't they laying down large flat side down?

And Matt is correct, the plywood will be laminated to each other, and once prepped, the plywood assembly will be installed on the interior side of the boat's transom skin.