Re: 1958 14' Fleetform

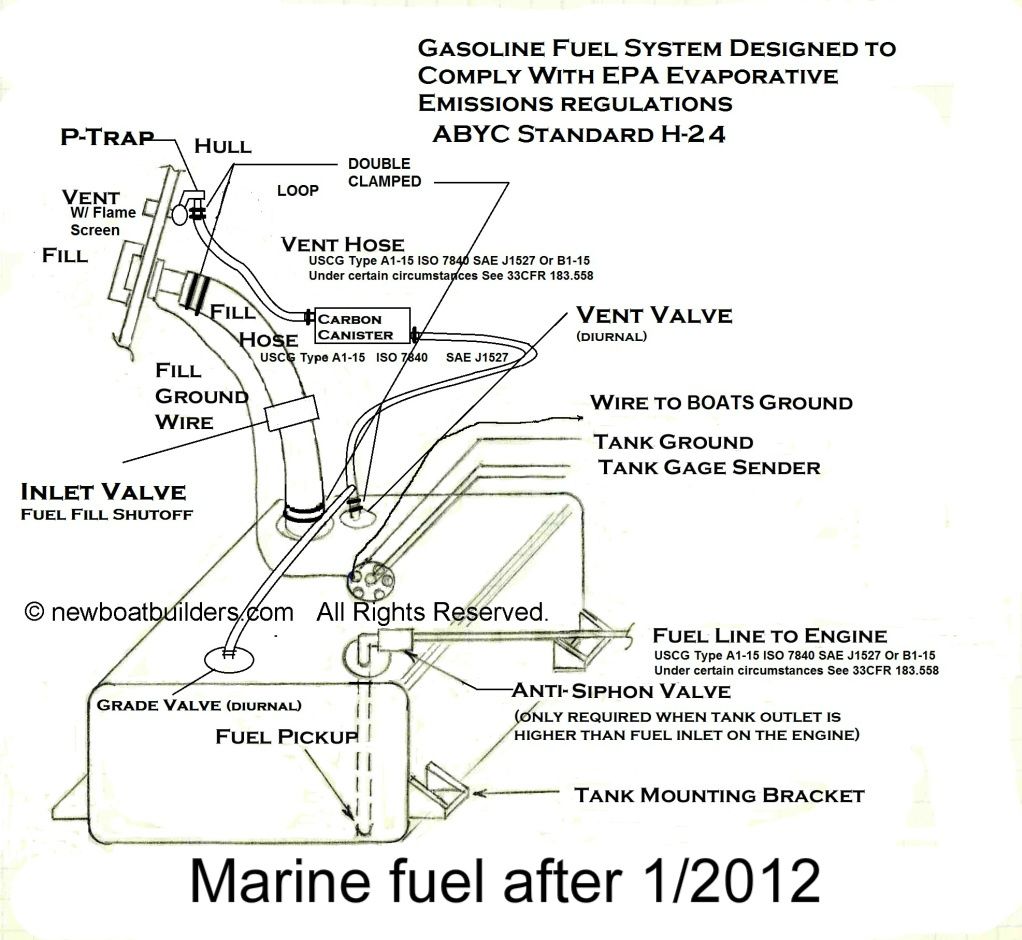

Underfloor fuel tanks need to meet these regs:

Making your own fuel tank. What are the legal rules?

[CITE: 33CFR183.510][Page 777-778] TITLE 33--NAVIGATION AND NAVIGABLE WATERS CHAPTER I--COAST GUARD, DEPARTMENT OF TRANSPORTATION (CONTINUED) PART 183--BOATS AND ASSOCIATED EQUIPMENT--Table of Contents Subpart J--Fuel Systems Sec. 183.510 Fuel tanks. (a) Each fuel tank in a boat must have been tested by its manufacturer[[Page 778]]under Sec. 183.580 and not leak when subjected to the pressure marked on the tank label under Sec. 183.514(b)(5). (b) Each fuel tank must not leak if subjected to the fire test under Sec. 183.590. Leakage is determined by the static pressure test under Sec. 183.580, except that the test pressure must be at least one-fourth PSIG. (c) Each fuel tank of less than 25 gallons capacity must not leak if tested under Sec. 183.584. (d) Each fuel tank with a capacity of 25 to 199 gallons must not leak if tested under Sec. 183.586. (e) Each fuel tank of 200 gallons capacity or more must not leak if tested under Secs. 183.586 and 183.588.[CGD 74-209, 42 FR 5950, Jan. 31, 1977, as amended by CGD 81-092, 48 FR 55736, Dec. 15, 1983][CITE: 33CFR183.512][Page 778] TITLE 33--NAVIGATION AND NAVIGABLE WATERS CHAPTER I--COAST GUARD, DEPARTMENT OF TRANSPORTATION (CONTINUED) PART 183--BOATS AND ASSOCIATED EQUIPMENT--Table of Contents Subpart J--Fuel Systems Sec. 183.512 Fuel tanks: Prohibited materials. (a) A fuel tank must not be constructed from terneplate. (b) Unless it has an inorganic sacrificial galvanic coating on the inside and outside of the tank, a fuel tank must not be constructed from black iron or carbon steel. (c) A fuel tank encased in cellular plastic or in fiber reinforced plastic must not be constructed from a ferrous alloy.[CGD 74-209, 42 FR 5950, Jan. 31, 1977; 42 FR 24739, May 16, 1977] Sec. 183.590 Fire test. (a) A piece of equipment is tested under the following conditions and procedures: (1) Fuel stop valves, USCG Type A1'' or USCG Type A2'' hoses and hose clamps are tested in a fire chamber. (2) Fuel filters, strainers, and pumps are tested in a fire chamber or as installed on the engine in the boat. (3) Fuel tanks must be tested filled with fuel to one-fourth the capacity marked on the tank in a fire chamber or in an actual or simulated hull section. (b) Each fire test is conducted with free burning heptane and the component must be subjected to a flame for 2\1/2\ minutes. (c) If the component is tested in a fire chamber:[[Page 784]] (1) The temperature within one inch of the component must be at least 648 deg.C sometime during the 2\1/2\ minute test; (2) The surface of the heptane must be 8 to 10 inches below the component being tested; and (3) The heptane must be in a container that is large enough to permit the perimeter of the top surface of the heptane to extend beyond the vertical projection of the perimeter of the component being tested. (d) If the component is being tested as installed on an engine, heptane sufficient to burn 2\1/2\ minutes must be poured over the component and allowed to run into a flat bottomed pan under the engine. The pan must be large enough to permit the perimeter of the top surface of the heptane to extend beyond the vertical projection of the perimeter of the engine. (e) If a fuel tank is being tested in an actual or simulated hull section, the actual or simulated hull section must be of sufficient size to contain enough heptane to burn for 2\1/2\ minutes in a place adjacent to the tank.[CGD 74-209, 42 FR 5950, Jan. 31, 1977, as amended by CGD 77-98, 42 FR 36253, July 14, 1977; CGD 85-098, 52 FR 19729, May 27, 1987]

There is a wealth of info available, if you'd care to look for it, on iboats. That would prevent the getting ahead of yourself that's been mentioned many times. It is unfortunate that this has come up during the holidays w/ very little traffic @ iboats.

It doesn't take much to go from yeah fun to oh carp when boating. When it does, you can not just pull over and get out. Nor can anyone else unfortunate enough to be in the boat when things go sideways.

Resto your boat & then boat safely