BillaVista

Petty Officer 1st Class

- Joined

- Jul 1, 2013

- Messages

- 204

Re: Tore the transom ...how to repair? (pics)

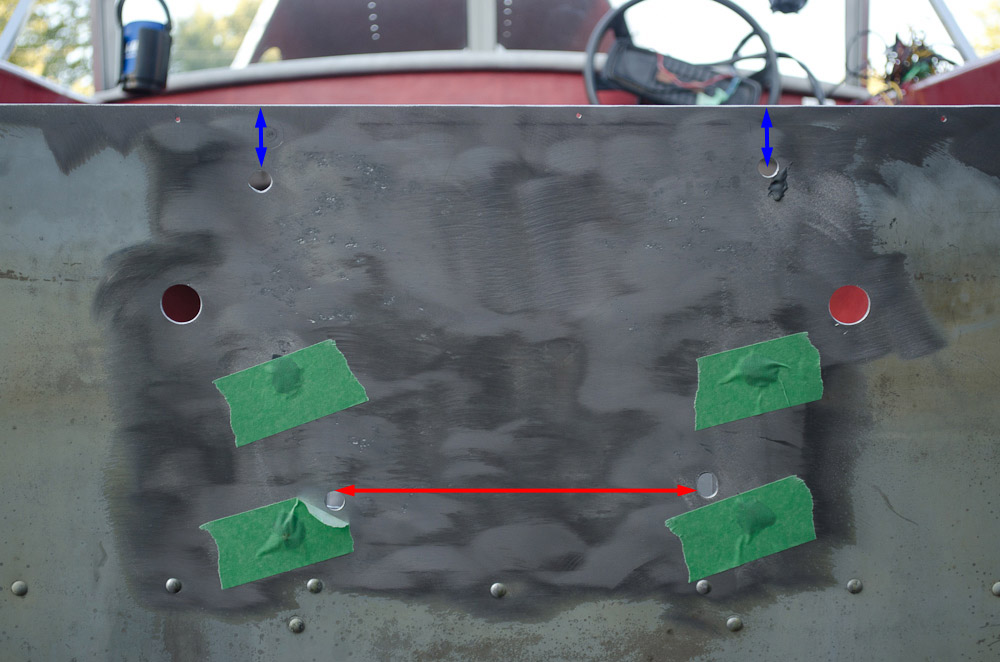

Epoxy going on the wood:

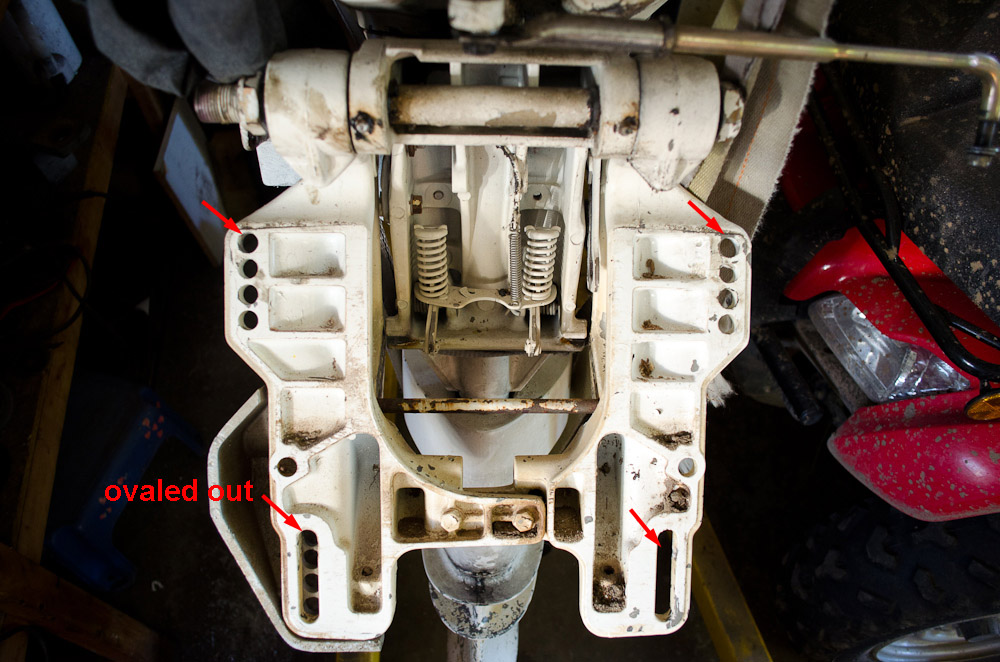

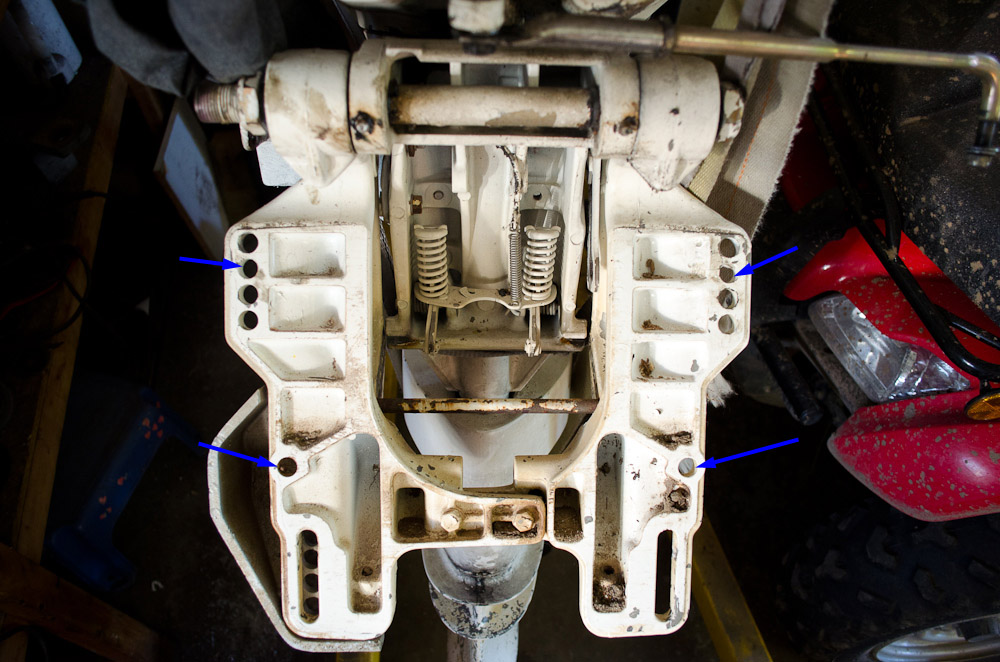

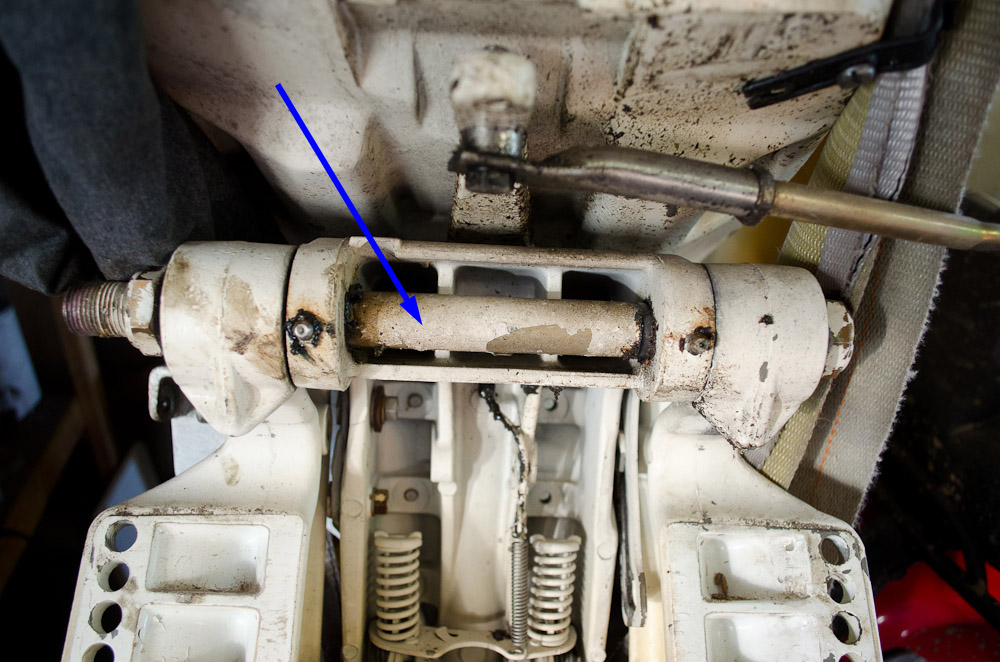

Rivets done. The home-made rivet gun worked well, as did the Evercoat bonding adhesive. The Admiral was a trooper in the boat with the sledge hammer (bucking bar)...but I should have given her hearing protection...the air hammer is loud when you are in the boat on hands and knees. We did an OK job - not great, but I think it'll do. The biggest problem was I bought rivets that were way too long. Second problem was getting the bucking bar (sledge) in place, especially on the rivets on the rib flanges, and double-especially on those where Starcraft had originally drilled the hole right up next to (and sometimes slightly into) the rib. Interestingly, I was worried about the air hammer being too hard-hitting, and installed an small inline reg. to limit the pressure...but ended up using it on full pressure anyway.

Epoxy going on the wood:

Rivets done. The home-made rivet gun worked well, as did the Evercoat bonding adhesive. The Admiral was a trooper in the boat with the sledge hammer (bucking bar)...but I should have given her hearing protection...the air hammer is loud when you are in the boat on hands and knees. We did an OK job - not great, but I think it'll do. The biggest problem was I bought rivets that were way too long. Second problem was getting the bucking bar (sledge) in place, especially on the rivets on the rib flanges, and double-especially on those where Starcraft had originally drilled the hole right up next to (and sometimes slightly into) the rib. Interestingly, I was worried about the air hammer being too hard-hitting, and installed an small inline reg. to limit the pressure...but ended up using it on full pressure anyway.