Re: Tore the transom ...how to repair? (pics)

Yesterday was a very good day.

Motor mounting day!

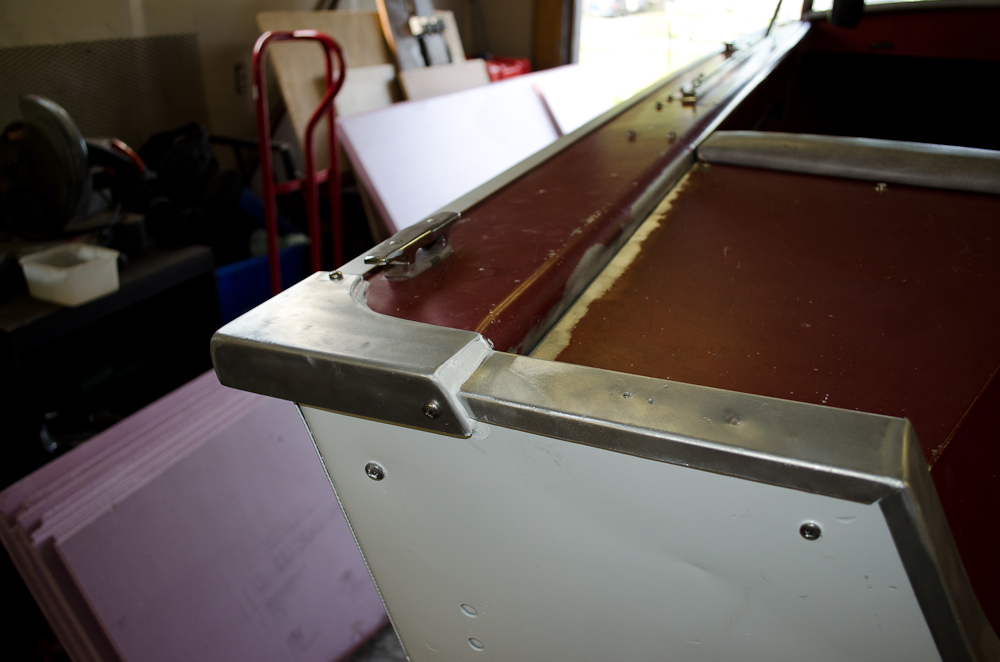

First thing to do was to mark a master line on the boat that was straight, square, and level. Has to be perfect (or really close to it), as everything else is built from that.

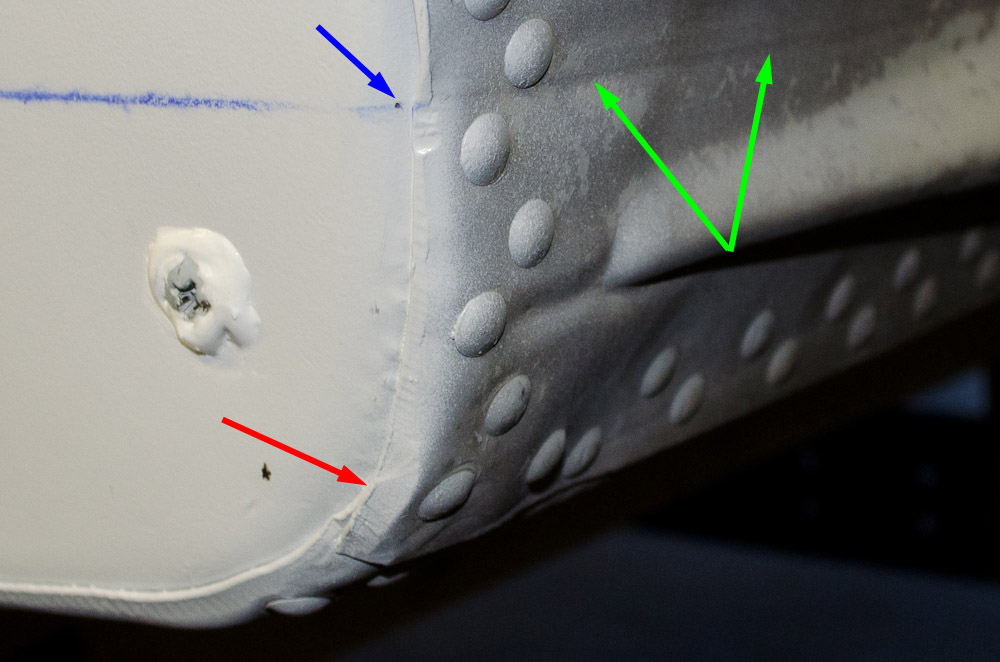

I started at the intersection of the side and the stern, right where the corners meet (red arrow). This was below where I has mounted the Smart Tabs, so to move it up, I set the corner of the ruler on this point and marked a point where the ruler intersected the side panel at exactly 3" (blue arrow). I did the same on the other side. These two marks became the points between which we snapped the blue chalk line that you see. This was our master line.

It wasn't until stepping back that we realized the my marks also lined up perfectly with the visible die marks on the side panels left over from when the stabilizing ribse were rolled in the side (green arrow)

Shot from further away.

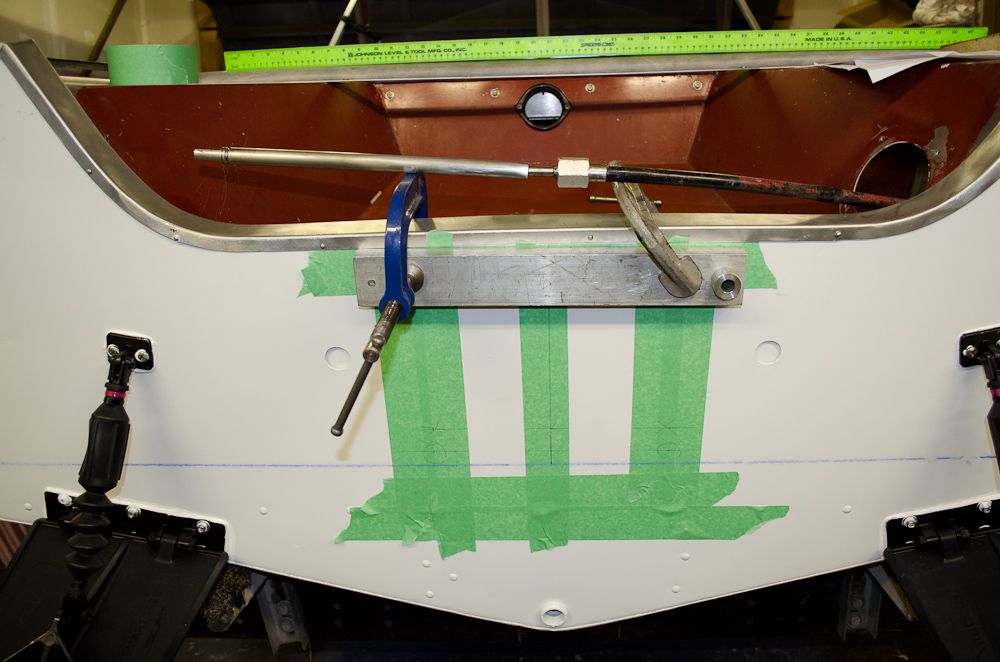

Next we laid some green masking tape on the stern so we could draw some prallel and perpendicular lines with a pencil. Then, by measuring, we laid out the the motor mounting bolt pattern by hand, using the standard ABYC dimensions (that I had confirmed my motor uses).

With the pattern laid out and double checked, we centre-punched the centres of the holes.

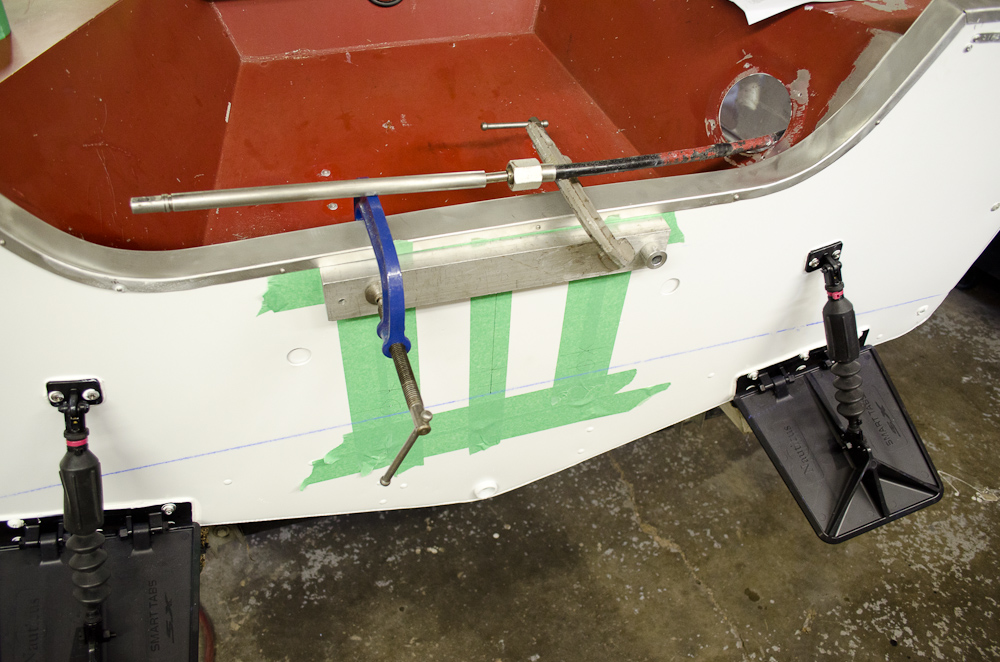

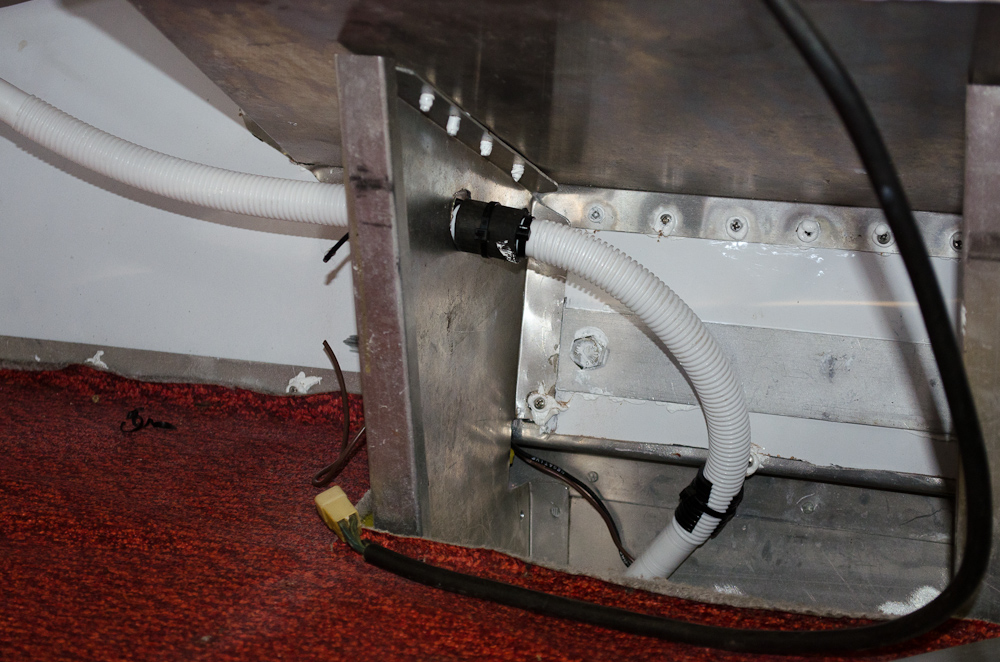

My good friend Justin who was helping me with all this (and who is also infinitely more patient and careful and talented than I am) made a jig to start and guide the drill bit exactly perpendicular (90*) to the stern out of scrap aluminum. Basically a bar to clamp to the stern with a big 1/2" bushing pressed into the end.

Looks like this:

In order to get it centred, we used a transfer punch, inserted in the drill guide. We used the transfer point punch to find and stick in the centre-punched mark, then aligned the drill guide and clamped it to the stern, ready to drill.

Then it was just a matter fo drilling the holse carefully, using the guide. I used fairly light pressure and high speed.