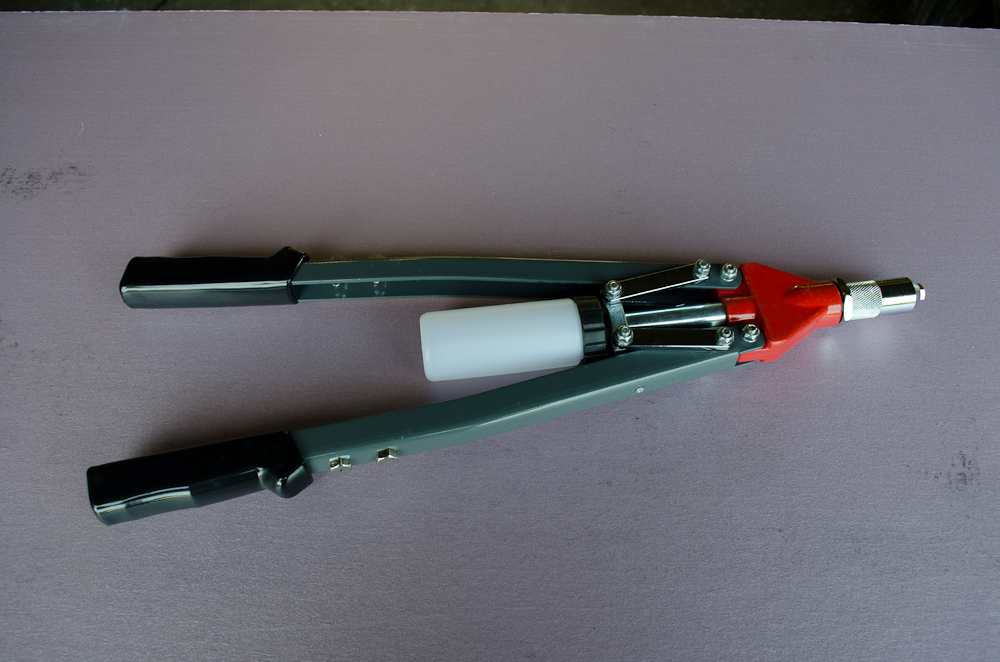

Re: Tore the transom ...how to repair? (pics)

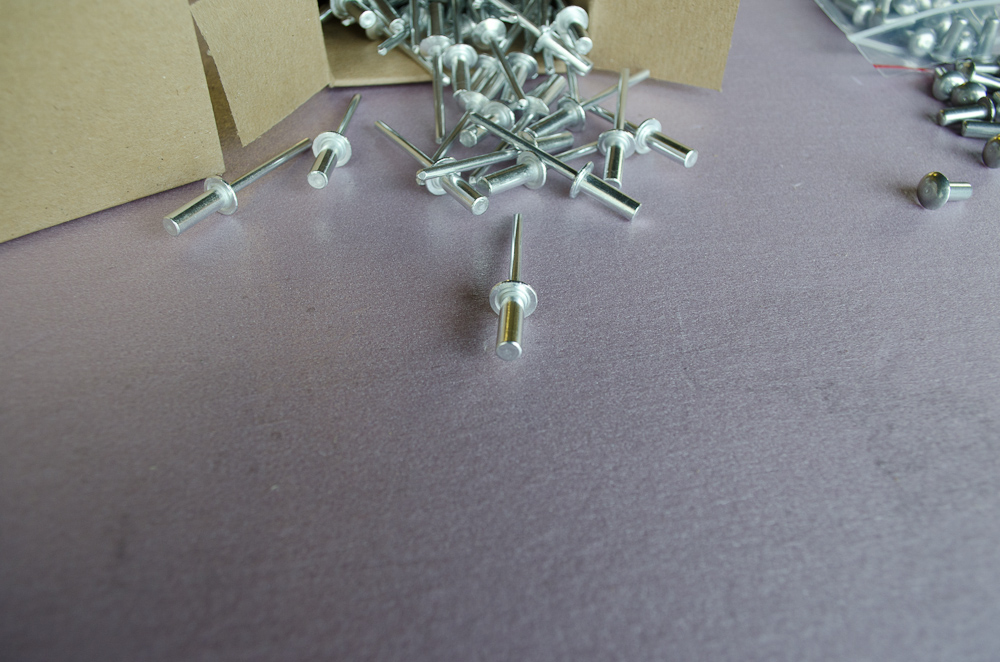

By the way, here's the epoxy I will be putting on the new rivets:

Large Panel Bonding Adhesive

Maxim™ Large Panel Bonding Adhesive is a one-to-one epoxy adhesive used for bonding various surfaces. It is used for replacing door skins, roofs, quarter panels, truck bedsides, utility vehicle sides and other non-structural panels. Maxim™ Large Panel Bonding Adhesive has excellent adhesion to SMC, cold-rolled steel, aluminum and e-coats. Maxim™ is backed by a lifetime warranty by Evercoat.

Work Time: 90-110 min

Clamp Time: 6 hours

Full Cure: 24 Hrs @ 21*C

Evercoat

DESCRIPTION: Maxim™ Large Panel Bonding Adhesive is a one-to-one epoxy adhesive used for bonding

various surfaces. It is used for replacing door skins, roofs, quarter panels, truck bedsides, utility

vehicle sides and other non-structural panels. Maxim™ Large Panel Bonding Adhesive has

excellent adhesion to SMC, cold rolled steel, aluminum and e-coats. Maxim™ Large Panel

Bonding Adhesive meets GM 6448G specifications and is backed with a full-life time warranty

by Evercoat.

FEATURES & Packaged in a Universal Cartridge: applied with a standard caulking gun

BENEFITS: 1:1 mix ratio

Contains glass beads for control of bond line thickness

Corrosion resistant properties: eliminates application of epoxy or self-etch primers

Excellent working times

Superior sag resistance

Easy to brush and spread

Cure time can be accelerated with heat

PREPARATION: Remove damaged panel. Grind surface area of the frame to remove old adhesive, rust and

other contaminants. Straighten damaged area. On quarters and roofs, grind the new panel to

bare steel. On doorskins, scuff the panel to remove the gloss.

Dry fit the panel to check for proper alignment.

Clean the mating surface areas of the frame and new panel.

APPLICATION: Equalize the cartridge to remove any air. Gun out a bead of adhesive the length of the static mix

tip to check for proper mix. Apply a bead of Maxim™ Large Panel Bonding Adhesive to the

frame and new panel. Brush the adhesive to a thin coat to cover all exposed bare metal. Apply

a 1/4” to 1/2” bead of the adhesive to the frame or new panel. Align the new panel to the frame.

Slide the panel to reposition. Clamp or screw the new panel to the frame. Do not remove the

clamps or screws for 6 hours. Remove all excess adhesive from the seams. Store used

cartridges with the tip down.

TECHNICAL

SPECIFICATIONS:

Appearance Gray/Black

VOC None

Odor Amine / mercapton

Working Time 90-110 minutes

Clamp Time 6 hours

Full Cure

Paint Time

24 hours @ 70? F (21?C)

8 hours @ 70? F (21?C)

Contents and Caution

Additional Information

MSDS available upon request