Re: hull extension in progress with picks

Re: hull extension in progress with picks

i get to post on the forum when im at work....as long as theres no customers

See, a man with priorities!

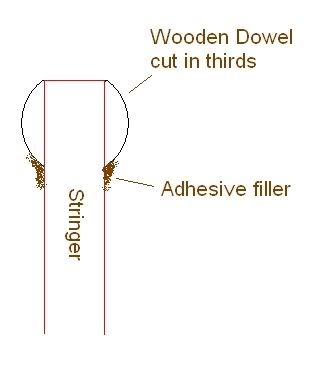

Say oops!, I was thinking again ( I know, bad idea ) about the stringer wrapping technique we all seem to be trying to figure out.

Since the glass you are using doesn't want to conform once it's wetted out..I can only assume partly due to the expansion as it fills in with resin, what about creasing the cloth? I mean, I'm not really familiar with anything but the little cloth sheets you get from the auto store ( I've got about 8 packets of them laying around here from god-knows-where ), so I don't have a lot of handling experience with the heavier stuff.

Can it be creased? My line of thinking is that the glass that is woven where it is essentially going to "bow" over the stringer is what is lifting the glass up and creating the air pocket. If you could crease that glass ( create a break line ), perhaps it would conform to the stringer better.

Or, would it just be easier to do more layups to get the thickness that you want, but use a lighter cloth that can conform to that curvature ?

I guess I'm having a hard time imagining in my head the stress on the top of the stringer. If you layed up heavy on the sides with thicker glass, and then ran a few layers over the top of the stringer cap, wouldn't you essentially get a "plywood" type effect for strength, and have a good bond with the sides of the stringer to avoid any stresses from lateral sheering?

It's the forces applied to the stringer and the proper glass layup that I'm trying to sort through my head, as well as the actual strength of bond between 2 separate layers of glass. Heady stuff here! Wheres an engineer when you need him/her ?