Re: hull extension in progress with picks

Re: hull extension in progress with picks

as i had mentioned earlyer........when i went to gellcoat the benches and the swim grid.......i had used PVA as a mold release agent....the pva needs to be atomised to be effective however it can be rolled or brushed on.

when i started to apply the pva with the gellcoat gun......it went off in the tubes......jammming the gun with in a moment!

pva washes off with soap and water.....so the gun was dissasembled and washes with warm water........it was a real pain in the ..........i ended up brushing the pva on to all of the moulds.

after that crazy session ....i was finally ready to shoot the benches and swim platform with gellcoat........noklu was right there helping....he was mixing and i was shooting the molds......every thing was going ok....

i should add at this time........ondarvr was in the area earlyer that week and we had talked about the shoot......i had only got a gallon of gellcoat, i had thought that was lots, but after doing the calculations with rvr.....i found out that i had too little gellcoat.

he suggested that i use fiberglass resin as an additive......mixed at a 15% ratio i had just enough to do the shoot in a pressuer pot hvlp.

we were also using ddm 30 at a 1.9% gellcoat/resin to catylest ratio.

the ddm 30 is the summer mix of mekp.....this allows a slower cure than mekp in hotter temps.....

that day i had the heat to 78 deg in the shop for the gellcoating.

the first part of the shoot went great!.... i shot the swim grid once then did each bench with the first coat of gellcoat.

thats when murphy showed up again!

after the first pot of gellcoat, noklu had another batch mixed up and ready....i opend the can and poured the next batch in the pot.......when i went to shoot it.....there was nuthing.....nope.....nada.....i opened the can up again, i found that the seal in the jar was toast and i didnt have a spare......i tryed to re-seal the can several times.....but to no avail.......

no klu quickly poured the gellcoat on to the mold and rolled it into place while i took the gun apart and dumped the thing into a can of aceitone.

one of the problems we had with rolling the gellcoat into place was that the mold was white......so was the gellcoat!so we really didnt know what thickness we were applying the gellcoat if any at all!.

sorry i didnt get pics of the gellcoating process....i was kinda busy!

after the gellcoat was applied and semi cured....i glassed the swim grid with a 1.5 oz layer of matt...(csm)

special attention was also paid to the edges of the swim grid.

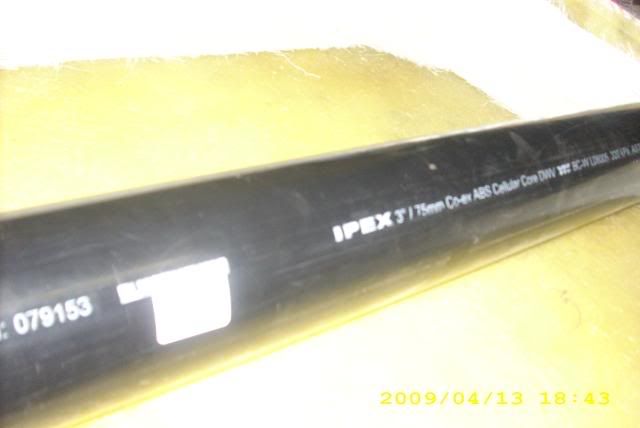

again.....as with all glassing.....each piece of fiberglass is cut and fit before the resin is mixed.....this is a 1708 biax

ondarvr suggested to make the corners thick....as thats where somebody will hit them at the dock.

the corners presented a special challenge as the glass was going in three different directions......easy with csm but not the biax......

oh.....by the way.....my faverout roller holder came into play here.