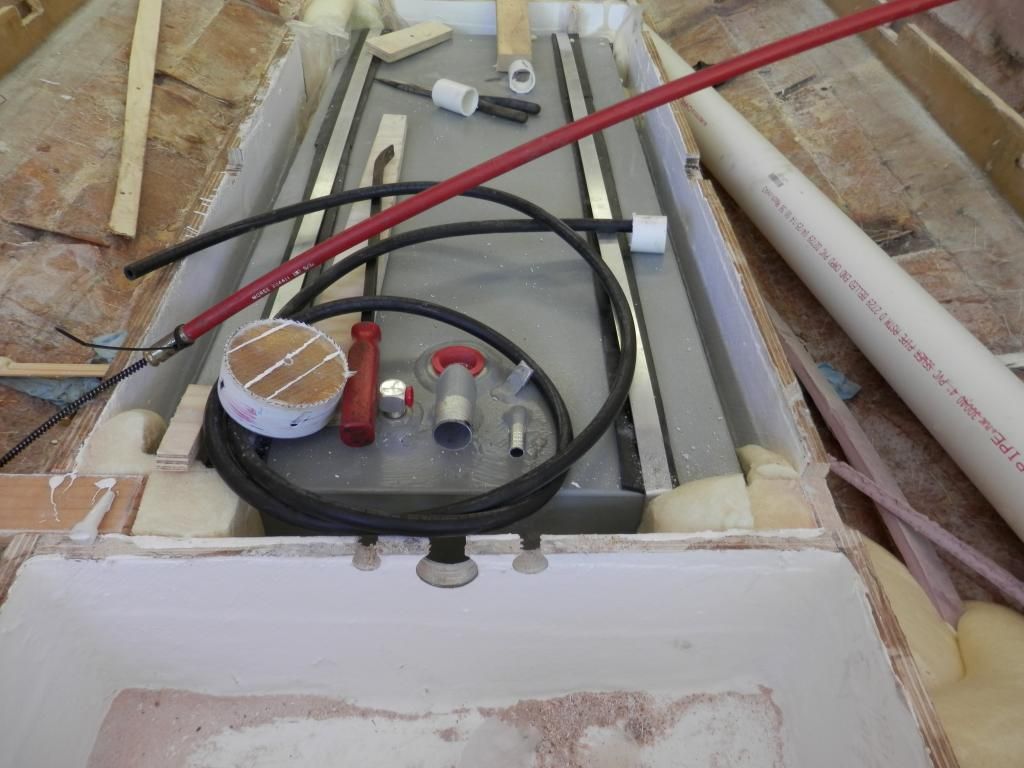

Question my bilge is obviously next to my fuel tank as seen in picture my deck is self baling so I do not expect to get alot of water in bilge should I drill a hole from fuel area to bilge just in case I get water in fuel area it has some where to go. I will have deck mounted inspection caps on both areas.

Also my last cut thru the hull is on the side above the water line its a 1" cut thickness of a saws all blade it will be covered from the inside with pb and deck tabbing do to where it is. If I get pb oozed trough will that be enough to seal it or should I alsso grind out the cut and repair outside

Also my last cut thru the hull is on the side above the water line its a 1" cut thickness of a saws all blade it will be covered from the inside with pb and deck tabbing do to where it is. If I get pb oozed trough will that be enough to seal it or should I alsso grind out the cut and repair outside

Also my last cut thru the hull is on the side above the water line its a 1" cut thickness of a saws all blade it will be covered from the inside with pb and deck tabbing do to where it is. If I get pb oozed trough will that be enough to seal it or should I alsso grind out the cut and repair outside

Also my last cut thru the hull is on the side above the water line its a 1" cut thickness of a saws all blade it will be covered from the inside with pb and deck tabbing do to where it is. If I get pb oozed trough will that be enough to seal it or should I alsso grind out the cut and repair outside