Looking good.

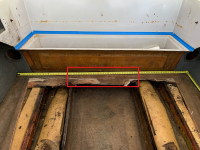

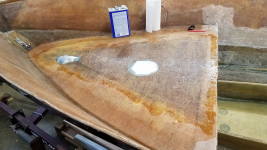

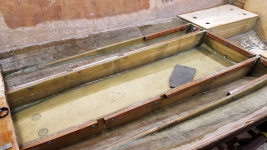

In my ski locker floor, I PB'd in the edges and put a single 1708 tabbing. Of course under the floor is open for drainage from the front of the boat (anchor locker) to the bilge. That being said, I then put a full layer of CSM down the stringer, across the floor, and up the other stringer. Then I did two layers of Gelcoat on top of all that.

For ski locker drainage, I put a 1.25 PVC threaded coupler through the rear of the floor and actually epoxied it in. I did the same in the Fuel Tank bay which you can see in my thread's picture (

post 181) . In the ski locker, I plan to actually screw a cap in to keep any water from backing up to the ski locker to keep it dry & allow for removal if water gets in there and needs draining. Unfortunately in the fuel bay, the tank will partially cover the drain; so, I can't cap it like I can in the ski locker.

Just thinking with all of the ski locker being so glassed and gelcoated in, I could use it as a live well when fishing . . . Nah, I don't think I want to fill it with water (LOL).