Question for the learned folks:

My 3/8" rubber fuel line originally was run under the deck, through a bulkhead and stringer, and was foamed in place. To me this is not conducive to future maintenance, and I'm not wanting to drill holes through my stringers and bulkheads if I can help it. See below for some pictures of how it was originally ran.

Is there any reason I shouldn't just run the new fuel hose up under the gunwale with all the wiring and steering cable? It would be the easiest, most serviceable way to run it, but are there any regulations against doing this? Any mechanical reasons (vapor lock, etc.) to avoid this method?

My second option would be to glass in a piece of PVC pipe along the inside of the hull on top of the deck that has an inner diameter big enough to pass the rubber fuel hose through. This could then be covered with the carpet and be mostly invisible to all but the most discerning eye. This way if the hose needed replacing, it would be as simple as pulling it out of the pipe and pushing a new one through. See the last picture below for a sketch of what I'm talking about.

Fuel tank under the bow, with the "kick panel" removed. You can see the rubber fuel line coming off the top of the tank go over the front bulkhead then under the deck.

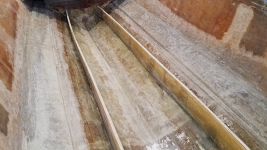

With the deck and rotten stringer partially removed, you can see the original path of the fuel line - it had pour-in foam over the top of it, then it goes through a hole drilled in the rear bulkhead and through another hole in the stringer to emerge in the bilge.

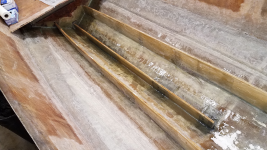

In this picture, the red line is my proposed location for the PVC pipe to pass the fuel hose through. It would be above the deck (no drilling through bulkheads/stringers required).