What usually do if finding the jets severely gunk/clogged is to soak them in paint thinner overnight, run a thin needle through both sides, or just squirt carb cleaner, but never ever poke any wire that doesn't count with a sharp point. Non pointy wires will end scratching the internal jet, but as long the internal diam remains as factory delivered, assume not an isue.

With respect of the seat micro polishing method, it's just to achieve a shinny finish look after the cotton comes out white clean. No need to go any deeper or keep polishing it peresecula seculorum LOL !!

Although the jet hole may look clean when placing it against a light source, I always poke them slightly with a thin needle at both extremes. On severely gunked jets the interal walls could narrowed a bit due to mini gunk layer formations sitting there. It's not my case as I always run my carbs dry.

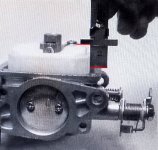

View attachment 331927

Don't worry if the third carb takes some microseconds to drop open, those carbs runs 50:1 fuel oil ratio which will lube the seat, needle, and float's arm when fuel enters the bowl at pressure.

Happy Boating