Re: Love, Necessity and Pride

Good day, gang!

Update...

Not much happening, but I did take a couple of steps backwards...

After much contemplation, I was quite concerned and convinced that I had somehow goofed on my initial aerator hook up...

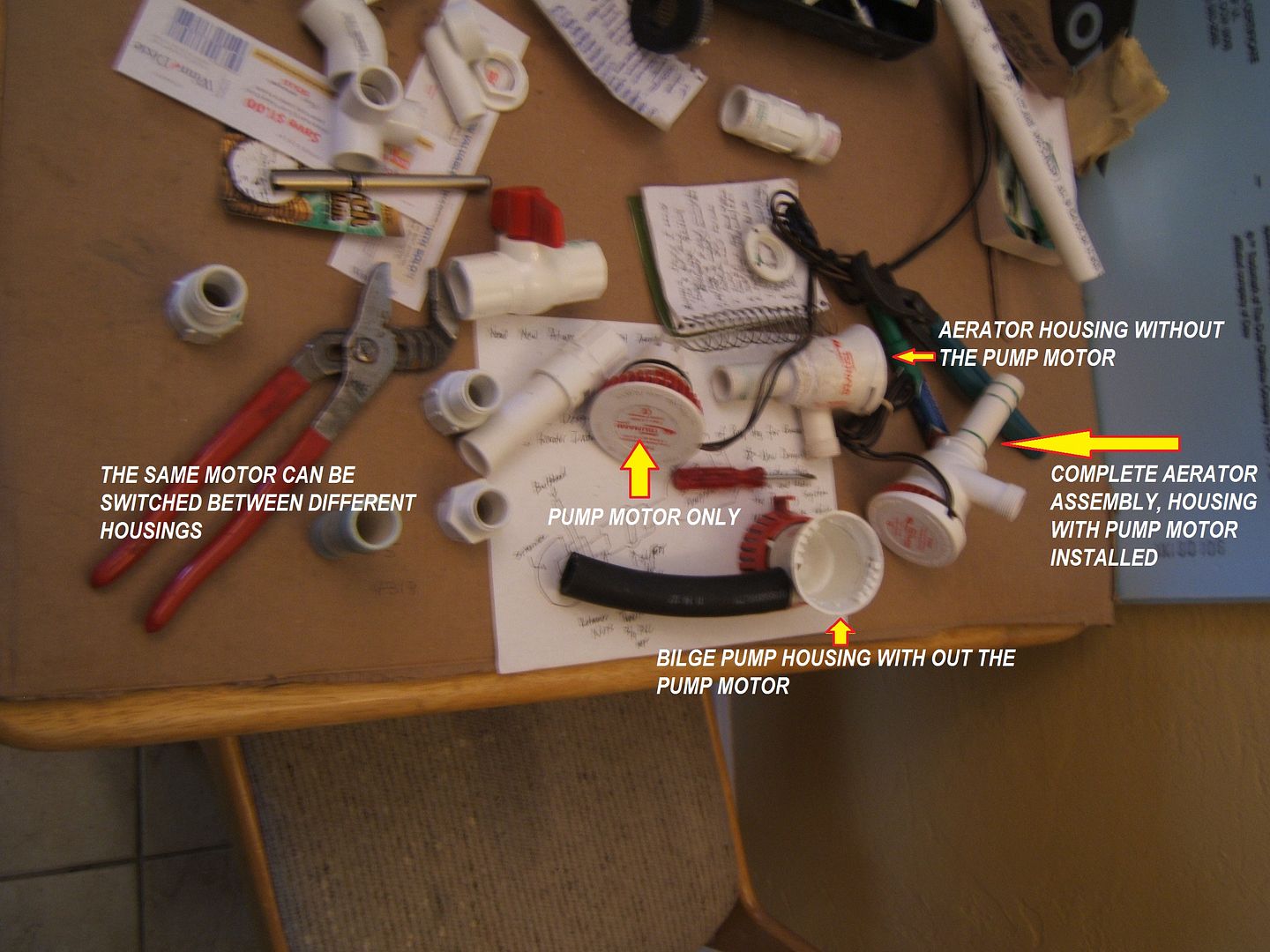

Ya see, IF, I ever had a bilge pump failure...the motor from the aerator could be removed and replace the one in the bilge pump...

But Wait!...

If I did remove the aerator pump motor from the housing, I would need a really

HUGE bilge pump to make up for the torrent of water that would come in through the 3/4" opening left behind by the removal of said pump motor...

Hmmmmm, not a good thing, me thinks...

So I decided the best course of action would be to remove the aerator housing and replace it with a new through hull fitting that would afford me a place to install a ball valve between the leak and the pump...

I wasn't too thrilled with this revelation since it would involve removing the housing from its rather permanent place, thanks to being sealed in place with 5200, and quite possibly ruining the housing from the amount of force I would have to apply to it, trying to "unscrew" it from it's location...

Well, decisions made...I would seek out a replacement aerator assembly in preparation for the possible destruction of the original housing, which in the end would give me an extra pump motor for back up use and redesign the water intake system with a way to shut off the entire contents of the whatever body of water I happened to be on, from entering the boat...

Let the fun begin...

Found a great price on the aerator assembly at the local Wallyworld, online, pre-paypalled, walked in, picked up and gone...

Came home and now it was time to tackle the original housing removal...laying on my back, on concrete, in the sweltering hot afternoon sun, Saturday, I began the dreaded removal operation...

After much cursing, swearing, grunting, some bleeding and cursing some more...

SUCCESS!

The pump housing came out, a bit scarred, but still quite servicable...OK, good, I can definitely find a couple of good uses for a complete working aerator...yay!

Then it was time to sit down and figure out how to make a "Modular" Thru-Hull fitting that would allow me to screw on the Intake Strainer on the outer end and the ball valve on the inside...

No where on earth could I find what I really wanted...A section of 3/4" Schedule 40 or 80 PVC about 6" long, threaded all the way...

Thought about going to a couple of plumbing supply houses nearby and asking if they could thread some for me...NOPE!, No way!...Go buy the die and do it yourself, they told me...or find a plumber to do it...OK, No thanks! The die costs between 60-80 bucks, I was only going to use once in my life and I really didn't feel like buying one, using it, then returning it...

Option

TWO...

Make something else work...

Grabbed a couple of MPT/slip adaptors, short section of 3/4" PVC, just enough to grab both adaptors and go all the way through the intake hole, glue one adaptor on the pipe, slip it in the hole, all slathered with 5200*[see note], clean the end protruding inside, grow longer arms to hold both ends while gluing the inside MPT adaptor on and pushing the whole mess together...wipe up any excess 5200 and walk away to let it all cure...

* Note: I realize I am spoiled by the great prices I have been able to obtain through out most of this build, and the amount I spent on the

smallest tube of 5200 I found is really just a drop in the bucket, compared to everything else...

I am still a little miffed that I had to spend almost 9 bucks for a

ONE OUNCE tube...Yeah they had the 3 & 10 ounce tubes for only a couple/few dollars more, but I just needed a very small amount and couldn't justify letting a larger amount go to waste...UGH!

End of Note...

Anyhow, enough ranting...

Here are a couple of pics of what all this blabbering is about...

Slightly scarred but complete useable, pump housing...

Planning and sketching out...

Hole cleaned and prepped for installation of new fitting...

New fitting installed, outside view...

Inside view...

That should work...now to just let it all cure, add an extra bead of 5200, still have more than 9/10 of my 1oz. tube left, around the inside fitting, then I can start really laying some pipe...

There are literally a ton of ways I could have accomplished the same basic outcome, but in my own little way, I had to figure out some way to make it complex...all is good in my world...

Have a great week, everyone!