Re: hull extension in progress with picks

Re: hull extension in progress with picks

a considerable amount of work was done on the boat in this session....

one of the things i wanted to do was fully speed dry the new exterior grade plywood....(my guys cut up all the pt for the strings)

in order to speed dry the wood...it should be cut and shaped..(less wood to dry)

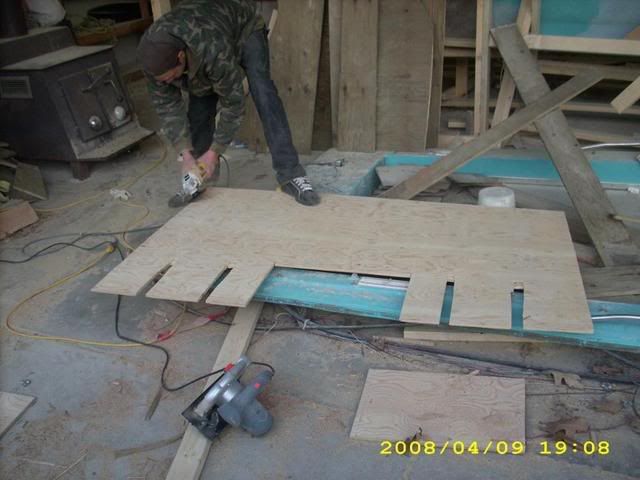

so we had to cut the deck...(sole floor)

once we got the beam cut...we layed the ply next to the knees...and marked the knees....then we cut the knees out

using a grinder....we shaved the ply to match the slope of the deck...the grinder makes quick work of this job

as you can see...quite a bit was removed for a good hull joint

using the same process...the rest of the peices were cut..

(that guy in the pic is quite a guy... just turned 20...hes been framing houses since he was 12..he is just about to take over the family business...a respectable framing company...when he isnt framing...he's working with me doing deleveries or on the road doing matress sales)

once the majority of the sole was cut, i had notch the stringers to take the under deck support frames

this was done with a circ saw to cut the depth...and then the jig saw to cut the width cuts....

these frames are cut every 4 feet on center...starting at the stern...

this will provide a good backing to screw the deck to.....

i will not be screwing these frames in to the top of the stringers....in stead..i will be glassing them in