Re: Fm161 1985

Thanks everybody but, using the plywood really does make this process quite simple and hard to screw up. For weeks off and on I would contemplate how I was going to bend this. I thought of different jigs, etc. that I think would work but, would require to much time and effort. Then the time came to do it. As I was walking to the fridge (for obvious reasons), I glanced at one of many piles of wood cutoffs. Then it hit me. One of those "Duh!" moments.

First figure your dimensions and cut your blank. I would suggest cutting too long and trimming after. Measure and mark your break points with an awl.

Now if you have access to a break , break into a channel. My aluminum was about .051. I would think this would be very hard on a siding/soffit break. I did mine on a steel break at work as my home break is only 4' wide.

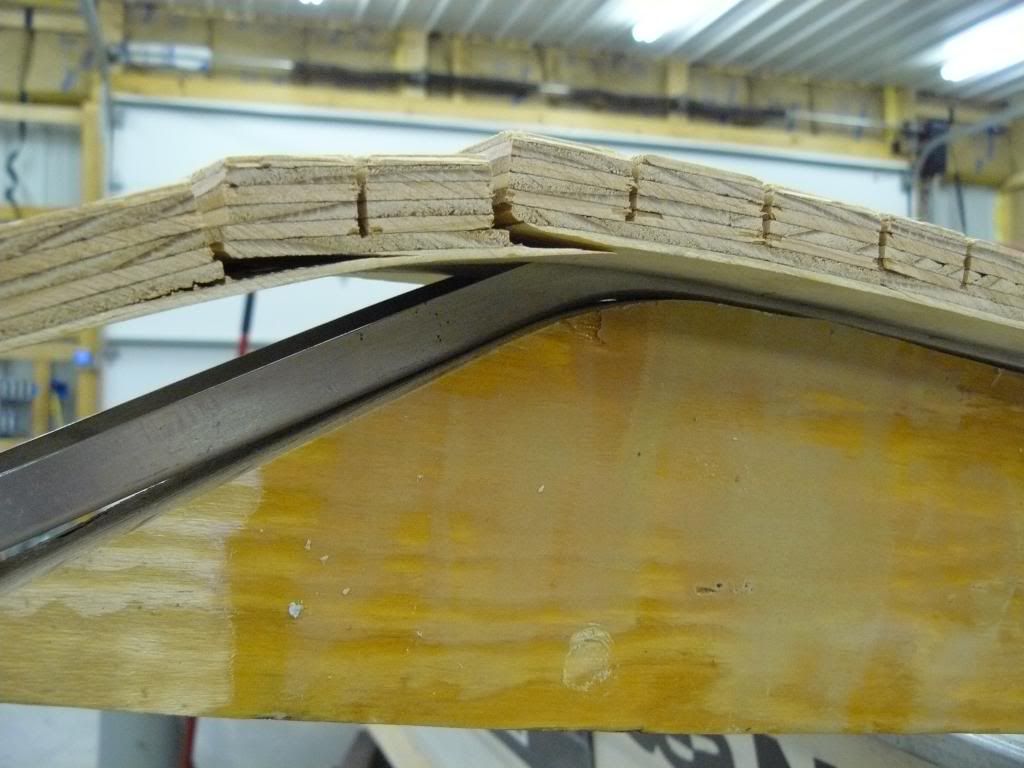

Now find a scrap of plywood from your new deck or transom. Cut longitudinal slots on one side, slightly deeper than the c channel

Then flip the wood and cut muliple, closely spaced slots allmost all the way through, perpendicular to the previous two slots

Then, locate your transom cutoff.

center your channel on the cutoff, slip on the ply and, flex the ply to form

Maybe I got lucky but, my bends turned out flawlessly

I think the trick is to keep the two slots as tight as possible on the aluminum. I used a cordless circular saw because it has a thinner kerf than my other saws