nola mike

Vice Admiral

- Joined

- Apr 22, 2009

- Messages

- 5,786

At this point you might as well cut that end and replace the cableYes. I did. It cannot be slide out even I pull it after I unscrew the square piece screw. I will do it again.

At this point you might as well cut that end and replace the cableYes. I did. It cannot be slide out even I pull it after I unscrew the square piece screw. I will do it again.

You should already have the shift cable disconnected from the shift plate, yes?I need to rebuild the bellows and it is last step to take of the bellows. Can anybody guide me to disconnect the shift cable in engine side?

Thank you Kris.You should already have the shift cable disconnected from the shift plate, yes?

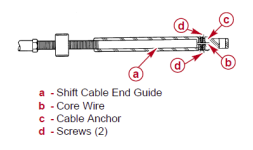

Loosen the 2 grubscrews on the end of the shift guide.

View attachment 359861

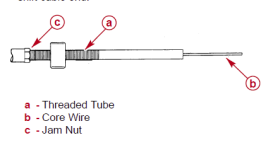

Pull the guide off. Loosen the jam-nut and then unscrew the threaded tube from the cable.

View attachment 359862

Now tie a length of cord to the end of the cable and with the bell housing pulled back, start pulling the shift cable out. Pull it all the way so you have the cord. Disconnect the cord and fit up your new shift cable bellows. Re-attach the cord and with a helper, feed the cable back in and guide it through with the cord...

What I would do with the cable pulled this far apart is the pull the inner out as well and clean it (and the inside of the shift slide) and squirt a SMALL amount of silicone spray on it before putting it back in.

Chris.......

Can it work if you do not drill the hole? But we can mark it.I bought my tools from Amazon, made by MBS Manufacturing: puller, driver, and alignment bar. It all worked. Yes, you have to mark/drill the hole in the alignment bar to mount the driver.

Hi Achris, Why does the manufacturing make a hole? if manufacturing cannot do so, that mean dealer or shop have to prepare thousand bearing driver for the installing different engine. How can I know the place I should make a hold at?No. Needs to be drilled for the pin to hold the bearing driver in place.

The standard Mercruiser special tool set has a driver bar and installation cups as a separate tool, not as part of the alignment bar. The aftermarket driver is one that was designed to be used with the alignment bar as the driver rod. That wasn't how Merc envisaged it, so no hole from the factory.Hi Achris, Why does the manufacturing make a hole? if manufacturing cannot do so, that mean dealer or shop have to prepare thousand bearing driver for the installing different engine.

Tomorrow I will buy a engine hoist and move away the engine and check the base and stringer.Did you check for rotten stringers?

If your stringers are rotten, and you are trying to bandaid the issue with a block of wood, is like pulling new pants over soiled underwear after you poop your pants. May look good for a moment

No, the engine is LOW if the bottom of the alignment tool touch more to coupler (so you need to make the front RISE), and the engine is HIGH if the top of alignment too touch more to coupler (you need to make the front DOWN).Now I understand the alignment, the engine is high if the bottom of the alignment tool touch more to coupler and the engine is low if the top of alignment too touch more to coupler. But my question is which screw should I turn to adjust the height.

Thank Achris for your replying.No, the engine is LOW if the bottom of the alignment tool touch more to coupler (so you need to make the front RISE), and the engine is HIGH if the top of alignment too touch more to coupler (you need to make the front DOWN).

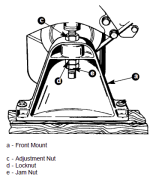

You don't turn the screw to adjust, you turn the nut ('c' in this picture) while holding the screw so it does not turn...

Loosen the jam nut about 10 turns. Back the lock nut away from the front mount about 9 turns, then use the Adjustment nut to raise or lower the engine. Once you get it right, run the locknut up and tighten it (without turning the screw), then run the jam nut up and lock it against the lock nut.

View attachment 359979

Yes, that's correct. If you put the alignment bar in and there is more marks on the bottom, then the front of the engine is low, and you need to make the front of the engine up. Nothing confusing.the engine is LOW if the bottom of the alignment tool touch more to coupler (so you need to make the front RISE), and the engine is HIGH if the top of alignment too touch more to coupler (you need to make the front DOWN).