Reserector_

Chief Petty Officer" & 2021 Splash of the Year Win

- Joined

- Oct 15, 2019

- Messages

- 650

Today I put the bunny suit and respirator back on and started cutting on the bottom of the cap to expose the rotted wood that needs to be replaced.

Weapon of choice was an angle grinder with a cut-off wheel. Quick and risky.

I thought I got all of it, but there is s good bit more buried in the back.

Oh well. I didn't come this far to cut corners now. It all has to come out somehow.

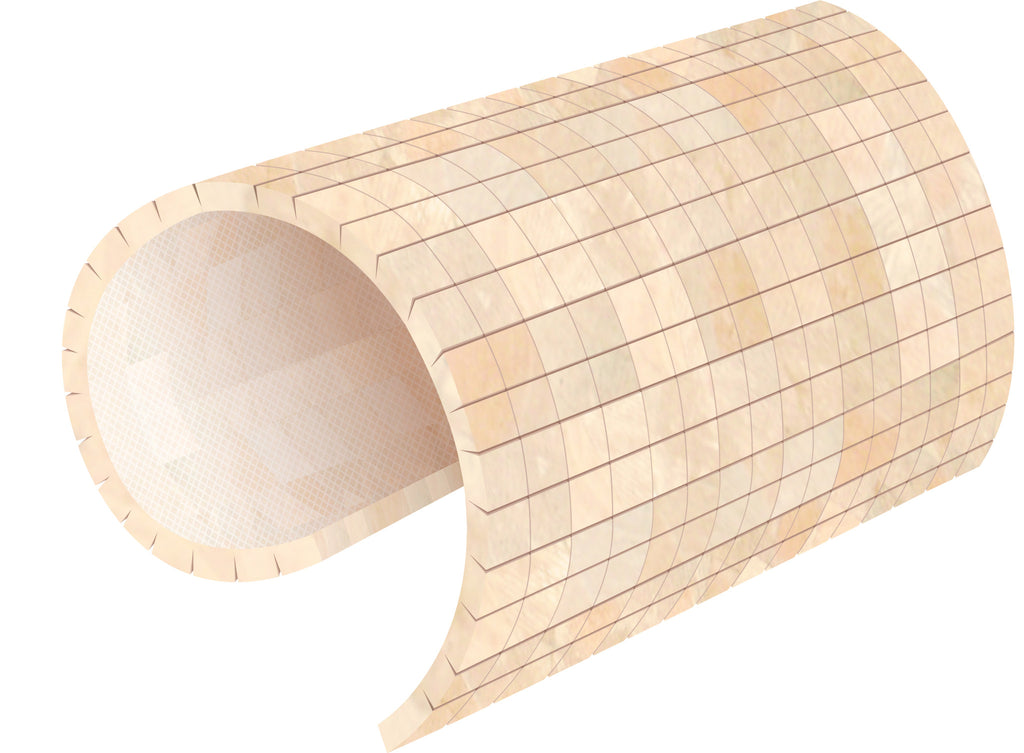

Question: have any of you seen plywood stiffening that looks like this? (7th and last pictures) It's like a bunch of rectangle pieces fitted together instead of a single sheet.

Maybe this area is not actually flat? Hmmm. I'll have to check out with a straight edge in the daylight.

Weapon of choice was an angle grinder with a cut-off wheel. Quick and risky.

I thought I got all of it, but there is s good bit more buried in the back.

Oh well. I didn't come this far to cut corners now. It all has to come out somehow.

Question: have any of you seen plywood stiffening that looks like this? (7th and last pictures) It's like a bunch of rectangle pieces fitted together instead of a single sheet.

Maybe this area is not actually flat? Hmmm. I'll have to check out with a straight edge in the daylight.