Reserector_

Chief Petty Officer" & 2021 Splash of the Year Win

- Joined

- Oct 15, 2019

- Messages

- 592

I've always gone for the ridiculous projects because they can be the most rewarding when done. This boat will be no exception.

The PO disassembled it and removed the rotten floor and stringers. It sat for five years and several small items were robbed off of it during that time. I ended up with it because I needed a small trailer for another project boat. I was told I could have it as long as I took the boat that was on it.

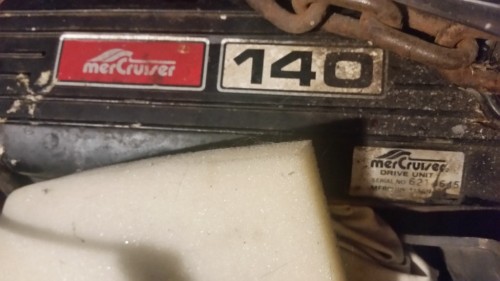

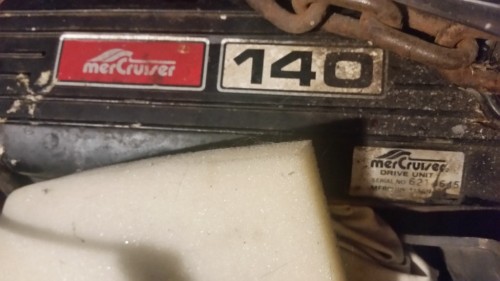

The trailer was too big for my needs, and the boat was junk at that point. Long story short, I hauled it off to help a friend who was going through a divorce. I later went back and got the garage-kept OMC/Mercruiser engine collaboration, the windshields, rub rail, bow rails, and a few odds and ends. In hindsight, I think all of the interior parts were in the garage, but I had no idea what I was looking at, so I left all that behind.

Here is how it looked when I towed it home. That is the cap on top, inverted and set into the hull. Loose junk piled in.

I just pulled it around back and parked it...for another ten years. Untill it looked like this with a hedge growing out of it. It was at this point that I decided I wanted to restore it.

I hauled it out into the light, cleaned it out, and took inventory of what was left.

The hull and cap were in usable condition, but with some small damaged spots that would need repair. But mainly, any wooden reinforcements that were not fully encapsulated in in fiberglass were gone. Termite food. Transom included. If there was a hole for a thing, and the thing had been removed, the wood is gone. Only a handful of reinforcements remain. All of the others will need to be replaced, unless I deem them unnecessary.

Some pics of the boat at the start of the project:

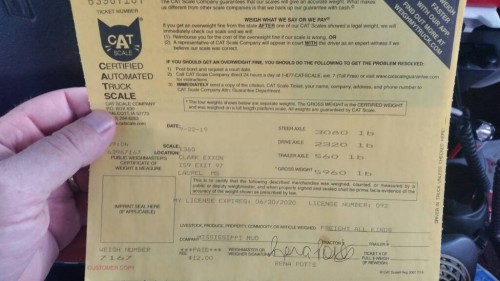

The seats are rebuildable. I only have the upper seat mounts, not the pedestals. The tank is brittle, so that will not be going back in. I have a frame for a ski locker. Steering was frozen. Tilt motor was frozen. Controls are stiff. Gauges are toast. The 1982 Mercruiser 4 cyl was a replacement for the original OMC. I'm told it has less than 100 hours on it. Teh outdrive seems servicable. Still full of clean gear oil, but now that I have rotated the shafts by hand, the oil is drooling out. Needs a full overhaul.

Pics of some of the parts that I pulled out and sat on a different old boat for the time being.

Stay tuned. More to come.

The PO disassembled it and removed the rotten floor and stringers. It sat for five years and several small items were robbed off of it during that time. I ended up with it because I needed a small trailer for another project boat. I was told I could have it as long as I took the boat that was on it.

The trailer was too big for my needs, and the boat was junk at that point. Long story short, I hauled it off to help a friend who was going through a divorce. I later went back and got the garage-kept OMC/Mercruiser engine collaboration, the windshields, rub rail, bow rails, and a few odds and ends. In hindsight, I think all of the interior parts were in the garage, but I had no idea what I was looking at, so I left all that behind.

Here is how it looked when I towed it home. That is the cap on top, inverted and set into the hull. Loose junk piled in.

I just pulled it around back and parked it...for another ten years. Untill it looked like this with a hedge growing out of it. It was at this point that I decided I wanted to restore it.

I hauled it out into the light, cleaned it out, and took inventory of what was left.

The hull and cap were in usable condition, but with some small damaged spots that would need repair. But mainly, any wooden reinforcements that were not fully encapsulated in in fiberglass were gone. Termite food. Transom included. If there was a hole for a thing, and the thing had been removed, the wood is gone. Only a handful of reinforcements remain. All of the others will need to be replaced, unless I deem them unnecessary.

Some pics of the boat at the start of the project:

The seats are rebuildable. I only have the upper seat mounts, not the pedestals. The tank is brittle, so that will not be going back in. I have a frame for a ski locker. Steering was frozen. Tilt motor was frozen. Controls are stiff. Gauges are toast. The 1982 Mercruiser 4 cyl was a replacement for the original OMC. I'm told it has less than 100 hours on it. Teh outdrive seems servicable. Still full of clean gear oil, but now that I have rotated the shafts by hand, the oil is drooling out. Needs a full overhaul.

Pics of some of the parts that I pulled out and sat on a different old boat for the time being.

Stay tuned. More to come.