Rickmerrill

Senior Chief Petty Officer

- Joined

- Mar 13, 2014

- Messages

- 686

One of these days, Nurseman, I'm gunna come up with something useful for ya but I got that feeling I'll learn ten times that from you!

Thanks for the vote of confidence Rickmerrill, but don't forget that I am a boating noob, so I'm sure that you will catch me on something before too long!One of these days, Nurseman, I'm gunna come up with something useful for ya but I got that feeling I'll learn ten times that from you!

Just going through your rebuild Nurseman .. I have to say you are doing an incredible job ! Love the grinding tent . Looks like it worked well and with a helper like you have keeping things straight, how can ya mess up ! As for the transom repair before the wood goes back in . My take is I kinda agree with Woody and jig .. I know thats kinda taking both sides . It.s probably not really needed but ya got it ground down and tapered back so well on your prep work I think I would at least put a layer or two of csm on it That way you won't have to worry about any pb oozing out the back . I am by no means an expert at anything so any advise from me should not be taken as 100% accurate .. :lol:

Keep up the great work ! SP...

what wood are you using for the transom, stringers, and deck?

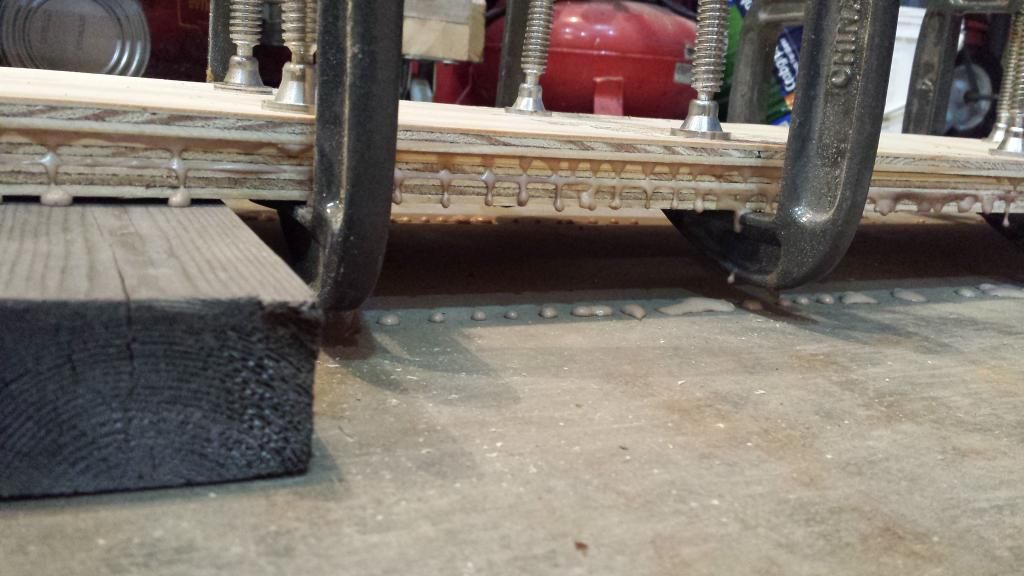

First stringer looks great. How many layers of what thickness did you end up using? That is yet another disgusting display of clamp wealth!

Wow nurseman, looks really impressive. Clearly your years of working as a carpenter are showing. Your stringers look fantastic and well shaped for consistent gap for PBing to the hull. If you dont mind I'll tag along for the ride as I'm doing that same thing very soon.

Gidday from Australia

Kerry

Outstanding fabrication ! The ooze holes should make for a really strong bond ...

Top notch stuff ! :thumb: