nurseman

Lieutenant Junior Grade

- Joined

- Jun 2, 2013

- Messages

- 1,045

Ahhh, that could be where I saw it. At any rate, I used it tonight,and it was pretty slick!All coming together now ! I think I saw the bucket tipping contraption over on Deckers deck boat restore ..

I worked almost all day on this thing, but don't have a ton of progress to show.:grumpy: Took the stringers out and rounded the tops over, cut the backers for the deck seams (although I didn't take any pics, so I may not have), cut a bulkhead for the bilge, and made a piece for the bow eye reinforcement.

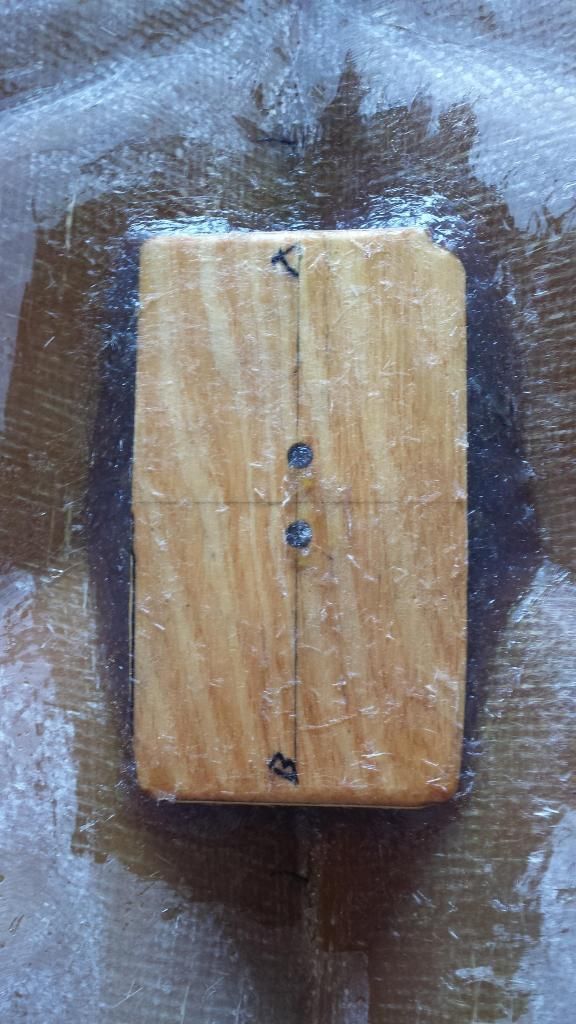

Then, because I wanted to mix some PB to get a feel for it, I decided to mount the bow eye backer. I mixed 100mL at .75% coated the block and let it soak.

Then mixed up 500mL of PB and mounted the block.

Then I wanted to try laying some cloth, so I cut a layer of CSM and a layer of 1708 to go over the mounting block, as well as three pieces of CSM to go over a hole in the keel.