Re: 77 Skeeter Restoration

Just checking in to say I'm following ya. Boat looks good!

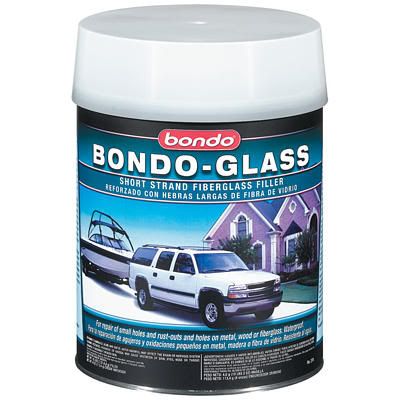

For the filler, the stuff I used has a green label with a picture of a house/truck/boat on it. I want to say it was $20/quart. Seems to have worked just fine for me.

I know it's kind of old, but I'm going to comment on the compressor topic. I had a small pancake compressor rated at 2.6CFM @90. I knew it wouldn't be up to the task, so I bought another small 3HP compressor and plumbed them together. I can't remember what it brought me up to (comparable to a 5HP unit), but it still wasn't enough to run a DA sander. I borrowed my dads DA and gave it a try and I was lucky to run it for 10 seconds before both compressors were on. That said, I do have a HVLP gun that I used and the setup worked perfectly. With the gun shooting at 35psi, I was able to spray continuously without both compressors kicking on. The slave compressor would fire on and run for a while to keep air supplied to the main tank, but the other one would never turn on. So long story short, a small compressor should run an HVLP fine, but I wouldn't even think of running a DA unless you had significant setup to supply the air.

Just checking in to say I'm following ya. Boat looks good!

For the filler, the stuff I used has a green label with a picture of a house/truck/boat on it. I want to say it was $20/quart. Seems to have worked just fine for me.

I know it's kind of old, but I'm going to comment on the compressor topic. I had a small pancake compressor rated at 2.6CFM @90. I knew it wouldn't be up to the task, so I bought another small 3HP compressor and plumbed them together. I can't remember what it brought me up to (comparable to a 5HP unit), but it still wasn't enough to run a DA sander. I borrowed my dads DA and gave it a try and I was lucky to run it for 10 seconds before both compressors were on. That said, I do have a HVLP gun that I used and the setup worked perfectly. With the gun shooting at 35psi, I was able to spray continuously without both compressors kicking on. The slave compressor would fire on and run for a while to keep air supplied to the main tank, but the other one would never turn on. So long story short, a small compressor should run an HVLP fine, but I wouldn't even think of running a DA unless you had significant setup to supply the air.