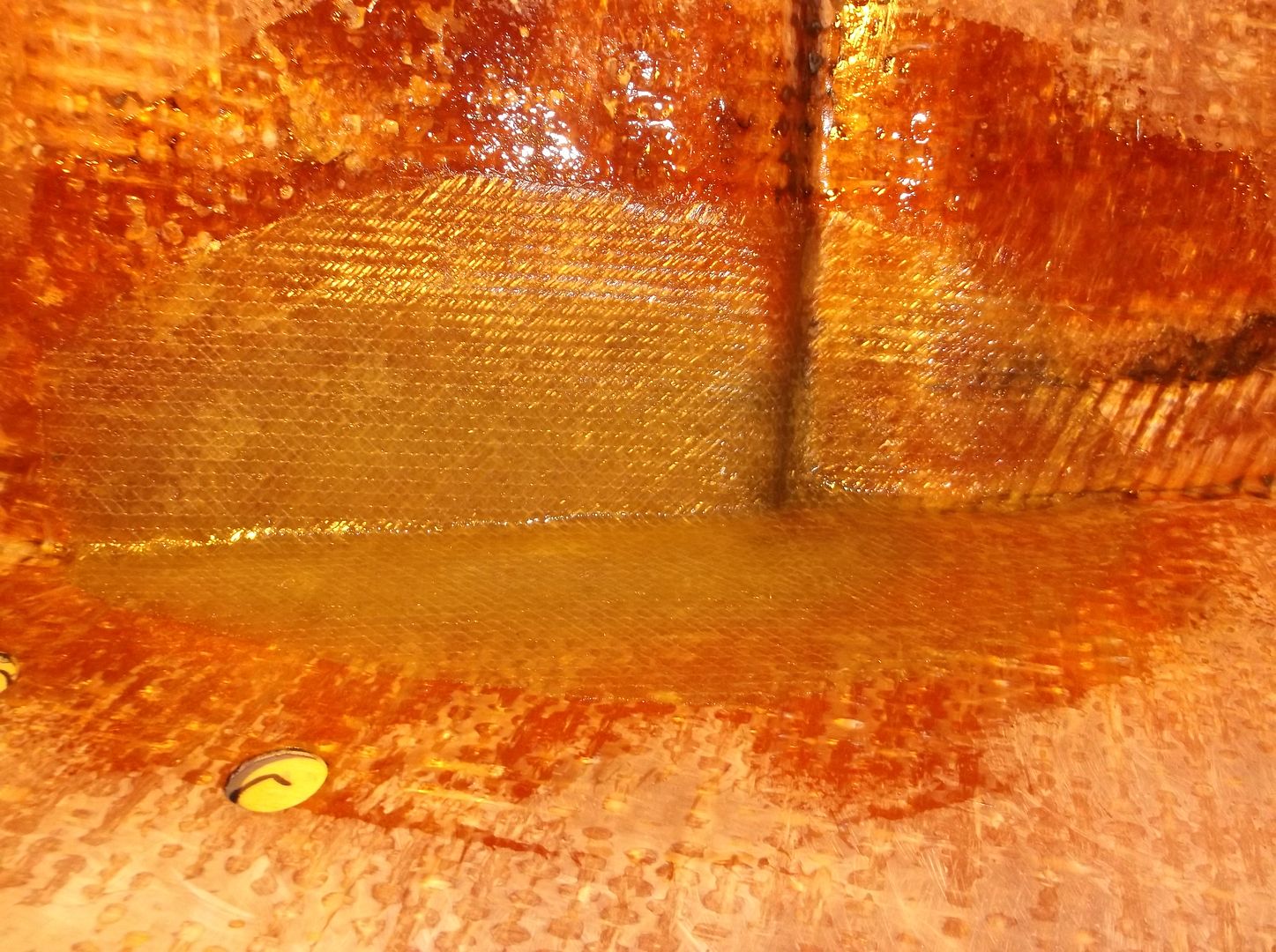

In picture # 2 above, there are two dark spots to the right and to the left of the frame. Check these. If they are contaminates, grind to a pink layer of glass like the surrounding areas.

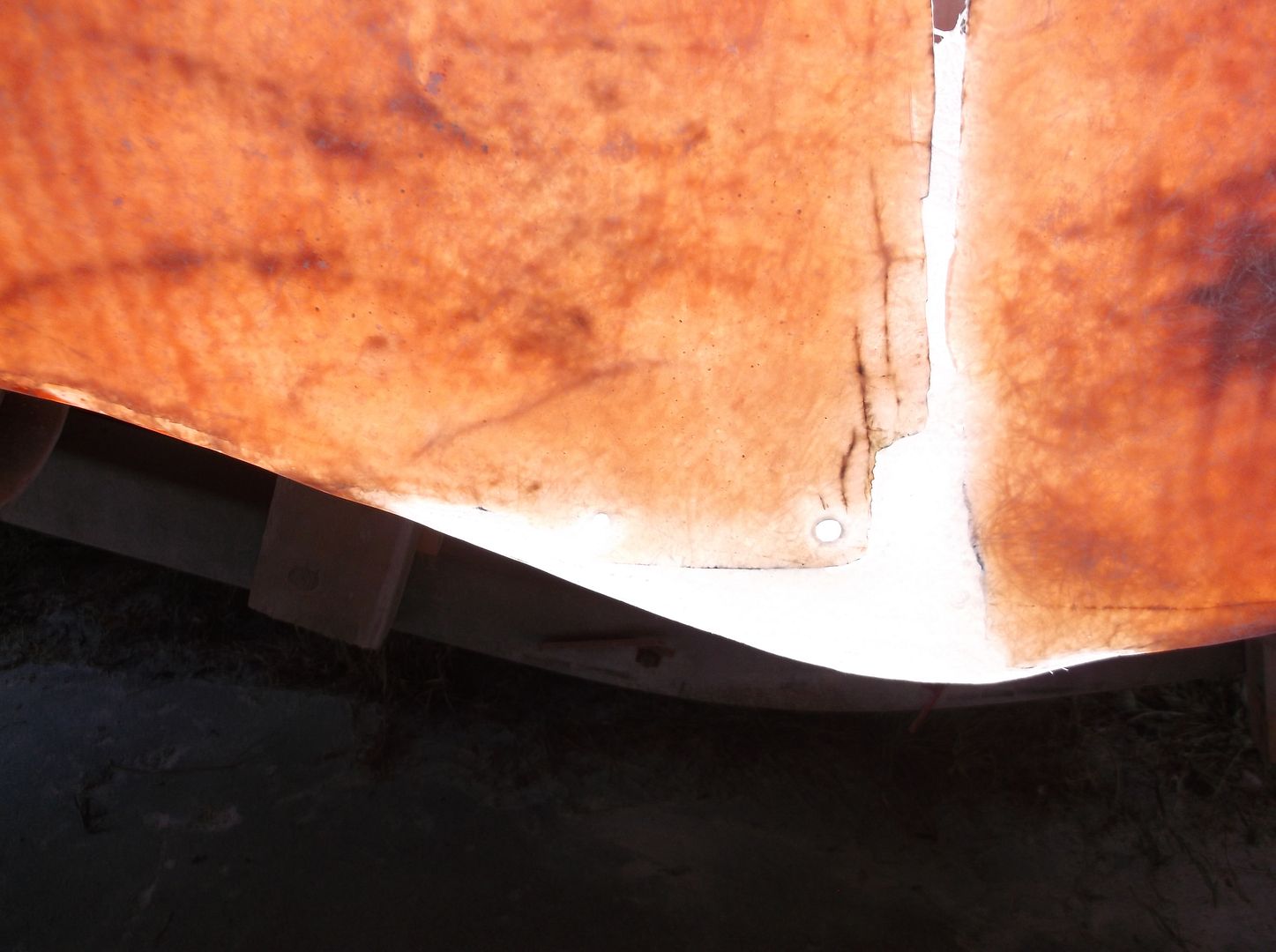

Get some wax paper, duct tape, cardboard and small cuts of PVC pipes of different radius. Start forming the backer plates on the outside as needed. use the PVC pipes to provide extra support under the turns and radius such as the chin line in picture # 5

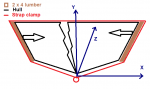

Clean the area to be glassed with acetone in one direction and switch the sides of your rag often. Feel the area with your hands and determine the deepest spot in the area. Trace the shape of this area on a transparent sheet with a sharpie pen. Cut the template and use it to cut a piece of 1708 the size of this area. Do the same with any other area that is not contiguous.

When you have enough piece to fill those deep areas and bring them on the same level (if you can't determine this, wait until you start glassing and see if they are filled or not, you don't have to glass it all in one session) Cut 3 pieces of 1708 so that the first one extends around the opening about 2 inches from all sides and each subsequent layer extends two inches from all sides more than the one before it.

Clean again with acetone. Don't skip this, it is important

Mix your resin based on your manufacturing recommendation for the ambient temperature that day/time. I would use vinyl-ester resin for this job.

Put your glass mat side down and make sure each one is saturated with resin with no dry spots. Use aluminum roller to remove any air bubbles and move the roller slow and steady from the middle toward the edges. Don't go back and forth in all directions in fast pace like some youtube videos are showing. Forget about the plastic ones, they don't last much. Prepare a container full of acetone to dip this roller in it when you done. Have it handy next to you.

When all your layers are glassed down nicely and all air bubbles are worked out. Go grab a beer or work on something else and let this resin cure for few hours or over night.

Remove the backer plates from outside. If your resin doesn't have wax in it (make sure of that when you buy) you don't need to sand from the outside.

Do the same thing from the outside to build up any thickness you took off with the grinder. Don't forget to clean with Acetone at least twice.

A good tip to avoid cursing during the glassing session is to buy some good quality gloves and wear at least 3 of them - one on top of the other - in each hand. This way, when one gets messy, just pull it off and you are still good to go.

Another tip is to mix your resin small amount at a time. Have the resin and the catalyst measure and ready for the next batch. If needed, mix them and continue. This way, you don't need to worry about measuring.