Shakedownscott

Petty Officer 2nd Class

- Joined

- Jul 12, 2011

- Messages

- 179

I have been slowly plugging away at the MFG project. Would like to have it closer to being done but its been a busy spring. After fitting in the fiberglass floor sections to make sure everything fit, I had to pull it back apart to cut out deck pieces and other pieces to put the flooring together.

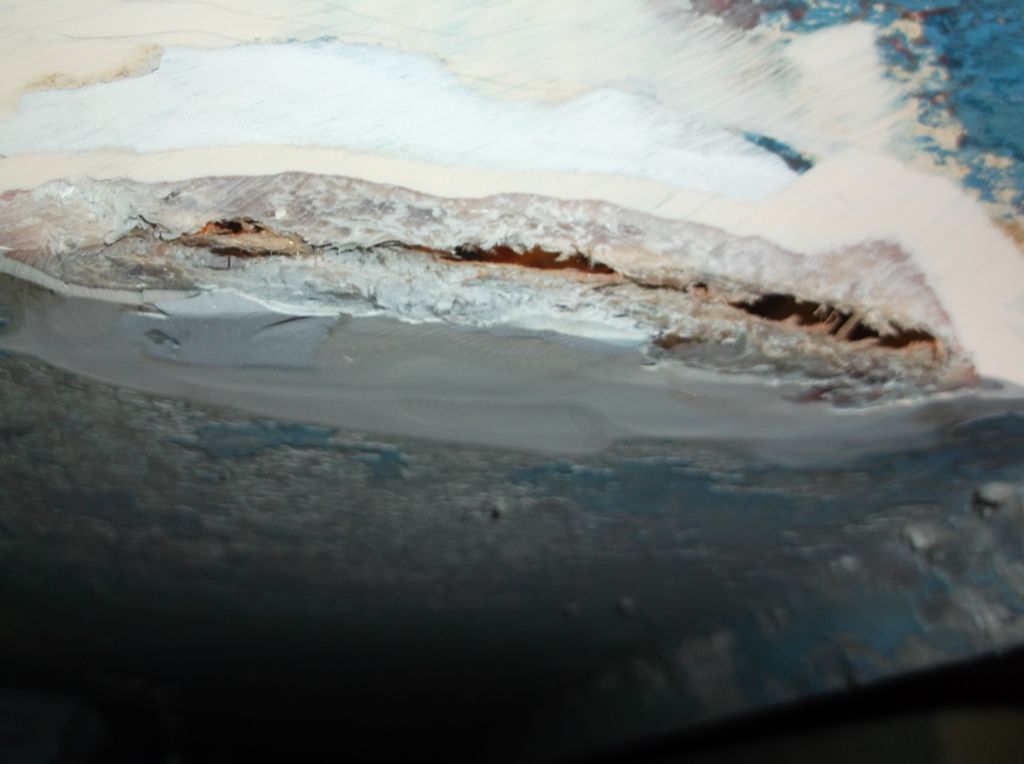

The boat originally had 3/4" plywood strips that went on top of the stringers, they were attached with strips of glass. I added cleats along the top of the stringers and secured them with stainless deck screws and PB.

I then got to play with expanding foam. The foam was pretty easy and fun to use, you just have to move fast.

I then used PB and deck screws to attach the 3/4" strips and 1/2" decking. The screws and nailers really helped to clamp down the new and existing floor sections. This made it pretty easy to make even before the PB kicked.

Everything hardened up really nicely and is solid as a rock. Next is the front part of the deck, then I can put the casting deck and gas tank back in.

The boat originally had 3/4" plywood strips that went on top of the stringers, they were attached with strips of glass. I added cleats along the top of the stringers and secured them with stainless deck screws and PB.

I then got to play with expanding foam. The foam was pretty easy and fun to use, you just have to move fast.

I then used PB and deck screws to attach the 3/4" strips and 1/2" decking. The screws and nailers really helped to clamp down the new and existing floor sections. This made it pretty easy to make even before the PB kicked.

Everything hardened up really nicely and is solid as a rock. Next is the front part of the deck, then I can put the casting deck and gas tank back in.