Goldie627

Lieutenant Junior Grade

- Joined

- Oct 28, 2013

- Messages

- 1,010

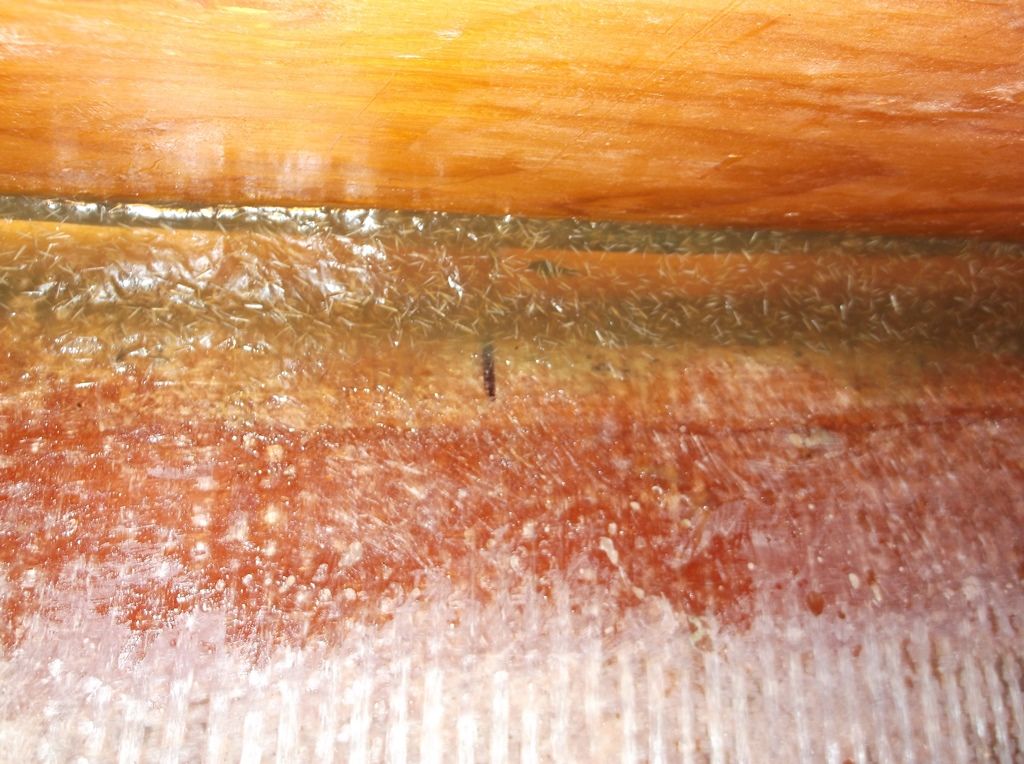

I kinda had a similar situation, wasn't as big of a gap as yours so I was able to get away with a jumbo fillet  . Only tip I can offer is if you decide to redo the foam with tape, watch out for air bubbles. Air bubbles/pockets are potential holding spots for water. I'm paranoid, so I would cut some strips contoured to the area, coat them with resin, then PB over that.

. Only tip I can offer is if you decide to redo the foam with tape, watch out for air bubbles. Air bubbles/pockets are potential holding spots for water. I'm paranoid, so I would cut some strips contoured to the area, coat them with resin, then PB over that.

Woody - You're batting 100% with me and a whole lot of other people here on the forum that you've unselfishly and continually helped over the course of your 20,000+ posts... "you tha man!" and classy, and humble, and... ok let me quit before I get kicked off this thread

Woody - You're batting 100% with me and a whole lot of other people here on the forum that you've unselfishly and continually helped over the course of your 20,000+ posts... "you tha man!" and classy, and humble, and... ok let me quit before I get kicked off this thread