harleyman1975

Ensign

- Joined

- May 12, 2003

- Messages

- 959

Understood. At the risk of sounding like a broken record...Very nice job my friend, very nice

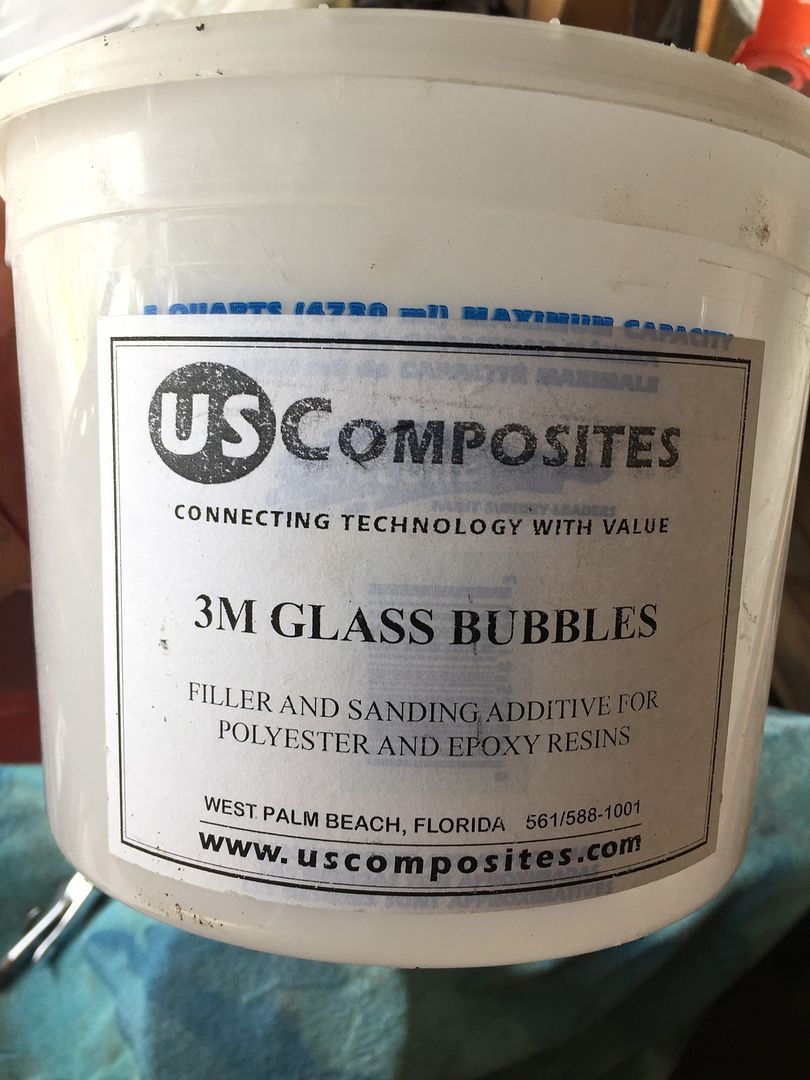

Well its been a few weeks and still plugging away at this boat. I gave up on the Hydraulic rams for now, I still cant figure why the port side has blown up 2 rams and on the starboard side the rams went up and down but very slow. I found 2 rams on ebay for a good price and they look like they were from a fresh water boat as advertised. They move very easily in and out by hand. I decided to put them on the starboard side since those rams look very salt water worn and were moving so slow. Now the starboard side doesn't work right. The rams travel all the way out, very slowly boat only retract a couple of inches and than stop so I gave up on messing with them for now. So back to the other stuff. I have mainly been trying to prep the hull and cap for painting. Its amazing how many holes, chips, nicks, dings, dents, cracks and blisters are in a 43 year old boats gel coat. The holes, chips, nicks, dings, dents, and cracks have been tedious to fix but doable the blisters as I have called them now that sucks. They are mostly on the bottom of the hull but there are a few on the sides as well. They are small cracks in the Gel coat most no longer than 1/2 or so with many having a slight half moon shape. If I take an awl/ice pick and lightly poke the Gel coat anywhere on the boat the gel coat is not damaged but if I poke these around these cracks the gel coat chips away and I find that the gel coat has separated from the fiberglass beneath it. So if I paint these areas the crack is only going to reappear and get worse so I have taken a Dremel and dug into the gel coat and the fiberglass just enough to clean away any loose gel coat. Some areas it is just the width of the Dremel bit and the visible length of the crack but other areas it ends up being anywhere from dime size up to half dollar size. Thankfully most of the spots are smaller then a dime but if I were to count them there are 100's of them. After cleaning away the loose Gel I blow them out with compressed air and wipe them down with Acetone. I then fill them in with resin thickened with glass bubbles and fairing compound. After it hardens then I get to sand them all back flush, oh the joys. Its really been fun working under the boat trying to squeeze under the trailer frame and axles. I don't have any good pictures of these cracks or blisters prior to removing the loose gel but here are a few with the fairing compound filling the holes.