- Joined

- Jul 23, 2011

- Messages

- 52,103

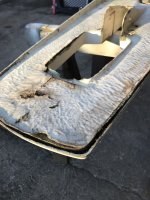

I would make test drills into the flotation boxes and the bulkhead in front of the motor. My bet is you have more demo work ahead

I really wish I would have thought about chamfering the edges, I see how much easier it would have been.Took advantage of warm weather here in the northeast and tried my first attempt at tabbing. Must say went better than expected. Did some tests first since Im using 1700 and epoxy resin. Wasn’t sure how much was needed to completely soak the cloth. Was much less than anticipated. View attachment 372720View attachment 372721View attachment 372722View attachment 372723

View attachment 372926

View attachment 372926