Re: 1988 Imperial 280sf engine swap and restoration (pics)

So I put some more skins on the second door, then ran out of propane....the torpedo heaters really suck a lot of juice!..so I didn't get a chance to do any shaping. So I went to work in the barn, removing the old stairs. I also got the utility room subfloor built.

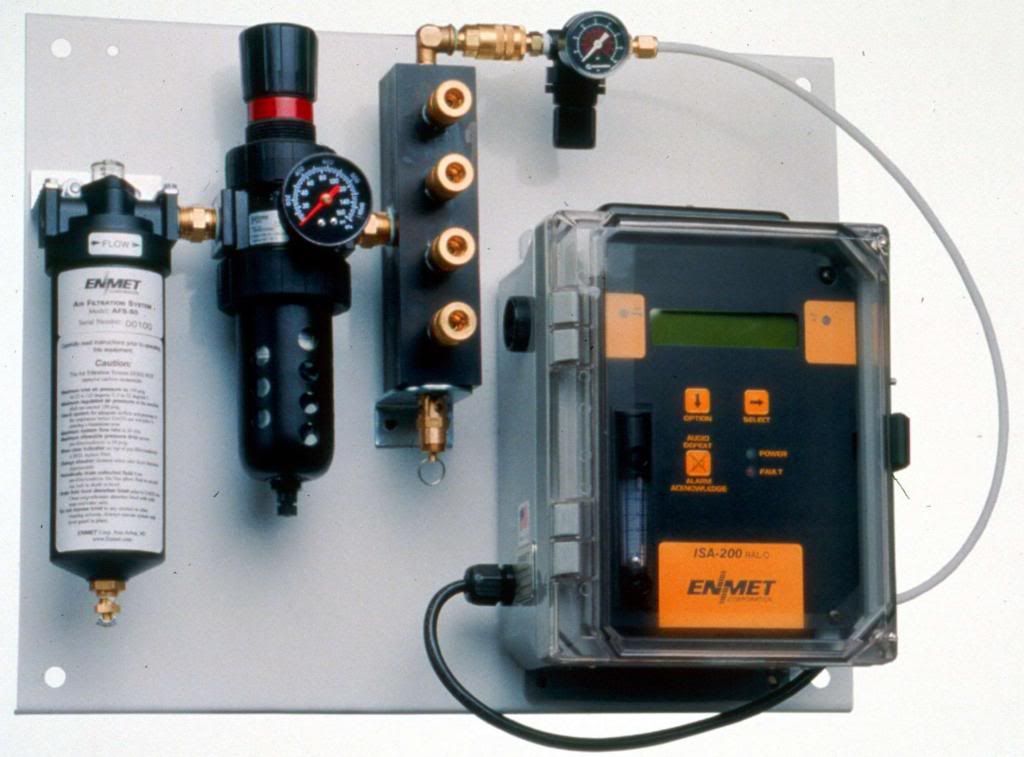

I'm getting close to putting in the air lines for the booth, but changed some plans. It seems the filtration needed to safely pull breathing air from the main compressor will be cost prohibitive....but I came up with an affordable plan. For anyone following the booth build, ill post the equipment im gonna use.

I framed out a closet in the adjacent mixing/storage area and wired outlets for the air dryer and turbine pump.

This is the 4x6 closet area

The idea is to use a supplied air pump in the closet with a greenhouse shutter wired to the pump switch. When the pump is turned on, the louvers open to allow outside air to the pump filter, which runs a hose to an out let in the adjacent booth. Then add another explosion proof switch near the outlet, to turn the air on and off without having to open the door.

Pump

Powered louver

The louvers will open and remain there til the pump is turned off. The system will be separate from the main compressor air.

Pump $169.00

Powered louver $150.00

Switch $65.00

It will supply positive pressure to the mask/hood, ensuring no ISOS get in..