Reserector_

Chief Petty Officer" & 2021 Splash of the Year Win

- Joined

- Oct 15, 2019

- Messages

- 650

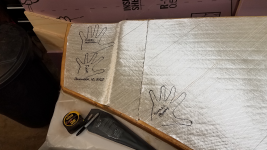

Clamp a scrap of plywood across the inside of the keyhole in the hull and check the "depth" from the outer hull surface to the plywood. That way, if you have any gaps that are going to hold off your plywood transom, you will be able to see and measure it.

PB might add another 0.040" like you say, but that won't be significant.

PB might add another 0.040" like you say, but that won't be significant.