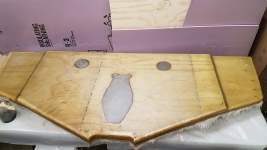

The Mercruiser drawings I found said transom thickness 2". 2 1/4" max. Watch that you don't make it TOO thick. I doubt you ground off much hull thickness. What was the total thickness with the new plywood in place?

I'd hate to see you lay up a ton of glass on the transom if it's not needed. If your thickness is good, you only need glass to seal it, and to strengthen the surface.

My boat originally had CSM half way up and a layer of gel coat to seal the wood. That's all. I glassed mine completely, and was approaching the 2 1/4" max. Barely had enough stud length on the lower part of the gimbal housing when I put it back together.

You already sealed the edges with CSM, so that's good. Just trim the excess off with a cutting disc on a grinder. Like a hot knife through butter.

Laminating resin on my build is still sticky in the ski locker where I plan to add carpet. A quick wash with acetone wakes it right back up, and cleans it, too. Fresh resin also softens the last layer, and that surface then cures with the new layer.

I tried sanding laminating resin once, but it was too gummy.

Don't PVA until you are done done. Only then will you use it on surfaces that won't get anything else. PVA, and then wash it down with water and a brush. Hose it off. You can really only do that when the glass work is finished.

You might do the floor, or inside of a compartment or something. Few areas, if any, will be left as bare resin.

Areas that get foamed can stay sticky.

Any time you lay glass on a surface such as the side of a stringer, keep it back from the edge that will be overlapped by tabbing. It can be close; you just don't want a frazzled edge.

Bring it all the way to the top edge, and trim it after it kicks. I used a router for that step. A grinder will take it down flush, too.