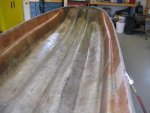

Todays update. With the rain and colder weather showing back up, I resorted to make the two main stringers. I have them ready now and I have to say for two really little stringers, they made me work on them for a long while. Being how they don't make exterior plywood in sizes larger then 4' X 8', I had to joint them together to make each stringer. Doh! So I lap jointed the pieces together and then glued two of them together to make one stringer giving me a solid 1 1/2" wide stringer. As you can see they are not very large and that actually made the joints even more interesting. I first made a cardboard version and transferred that to the plywood like everyone has done before. Nothing unusual there. But I thought that simple butt joints wasn't going to get it. So I set my radial arm saw up to cut exactly half way through the ply wood and made lap joints for every joint I needed. But I also staggered the joints so no two fell on the exact same area. And then I cut the first one out and made sure it worked. Once verifying it did, I cut more plywood sections and started gluing them together with lap joint. I used *** Bond III and clamps everywhere. I left them sit overnight to make sure they were dry before continuing. After they were totally dry, I took my Porter Cable router and a straight cutting pattern bit with a ball bearing on the end and used that to cut off everything that hung over the original pattern stringer. That gave me a perfect wide solid stringer. And I did the same for the other one as well. Then I took a belt sander and gave all sides a good smoothing and now they are ready. But only after I mix up some more PB and fill in the many voids exposed. Such totally crappy plywood to be top quality graded... But they will be solid before I install them. Now I have to work on the side braces and bulkheads for all the plywood joints from the plywood floor that meets together with each piece. Here are some pictures. I hope everybody can see how I assembled them and equally how small they are... I honestly believe larger height stringer would have been way easier. But it is what it is...

As you can see in these pictures I glued on pieces that actually over hung the pattern.

But the router with a pattern following bit made quick work of duplicating the original...

Yea, they have a little bend at the very end which is the smallest section. But I can easily straighten that out when installing...

So now some peanut butter mixture and some side sections and bulkhead at the plywood floor joints and I will be very far along...

How you all have a magnificent day... :thumb: