Now were getting somewhere ,,, I knew I could count on you GT for a bit of clarification / guidance . Very nice diagram and simplicity !

But you know me I got a ?

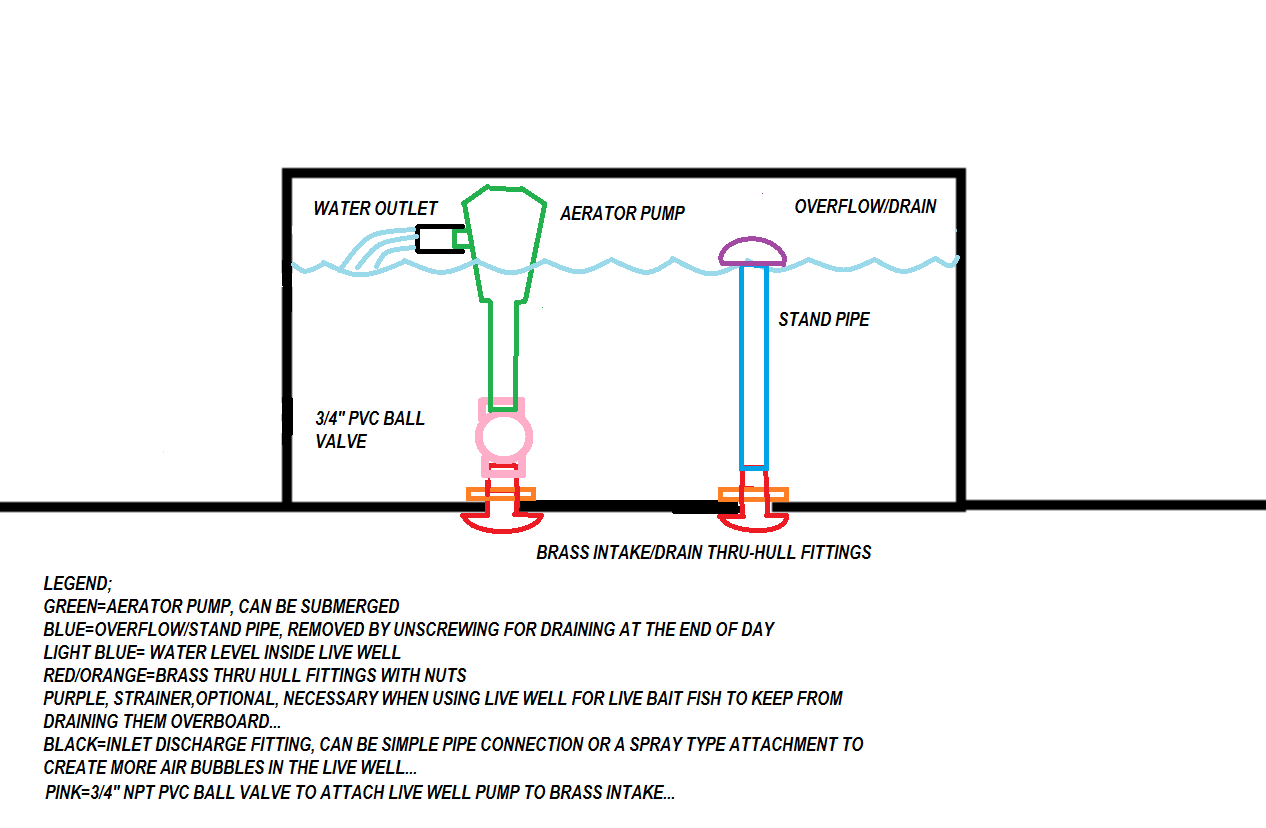

Will the water pressure under the boat especially while under way push up and over the top of the overflow tube ? And would you turn the ball valve off after you fill the well ? Ohhh one more ? Is there a different type fitting that could be used for the overflow that would allow all the water to run out of the well . Seems with the brass fitting it would leave a good bit of fishy water in the bottom ..

Thanks Gus this is very helpful !

I'll take those ??? one at a time...sort of

Be prepared because some of the following explanations can be a bit confusing, so feel free to ask for any clarifications and/or sketches...

As long as the top of the overflow is above the water level outside, water will not come in...as a matter of fact, if the boat is up on plane and you were to remove the stand pipe, theoretically of course, the water in the live well would actually get sucked out by a Venturi type effect, similar to how the air rushing through the throat of a carburetor actually pulls the fuel out of the bowl and into the engine...

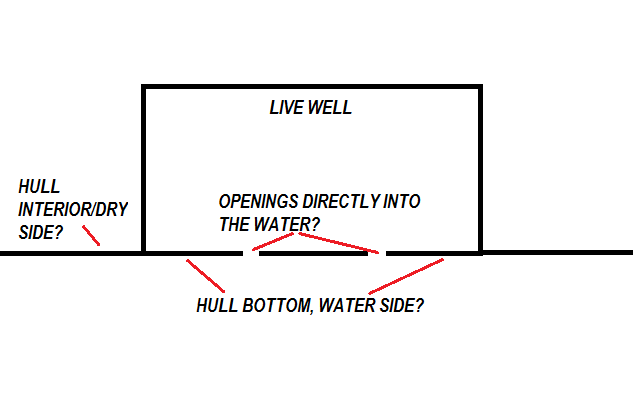

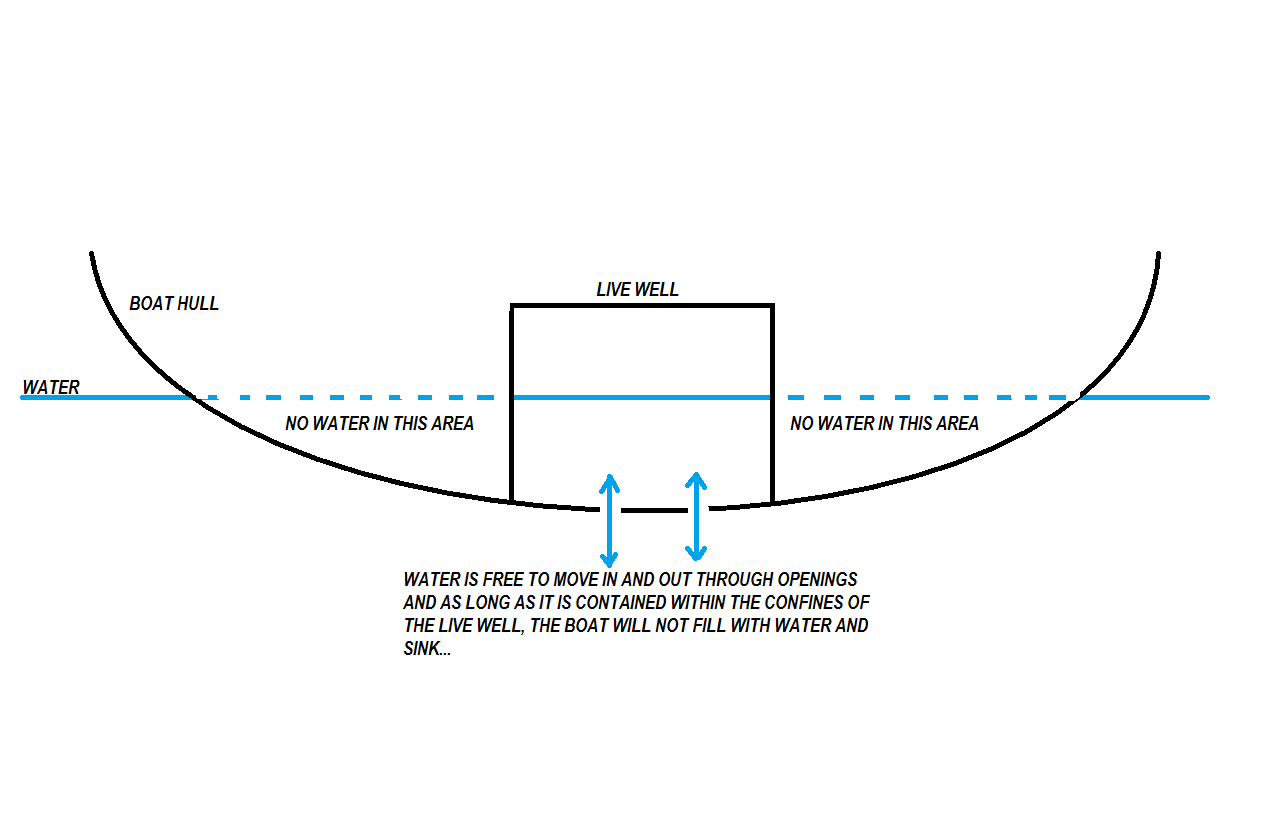

Technically, the ball valve or the stand pipe are not really necessary in this type of live well set up... see the first sketch below...

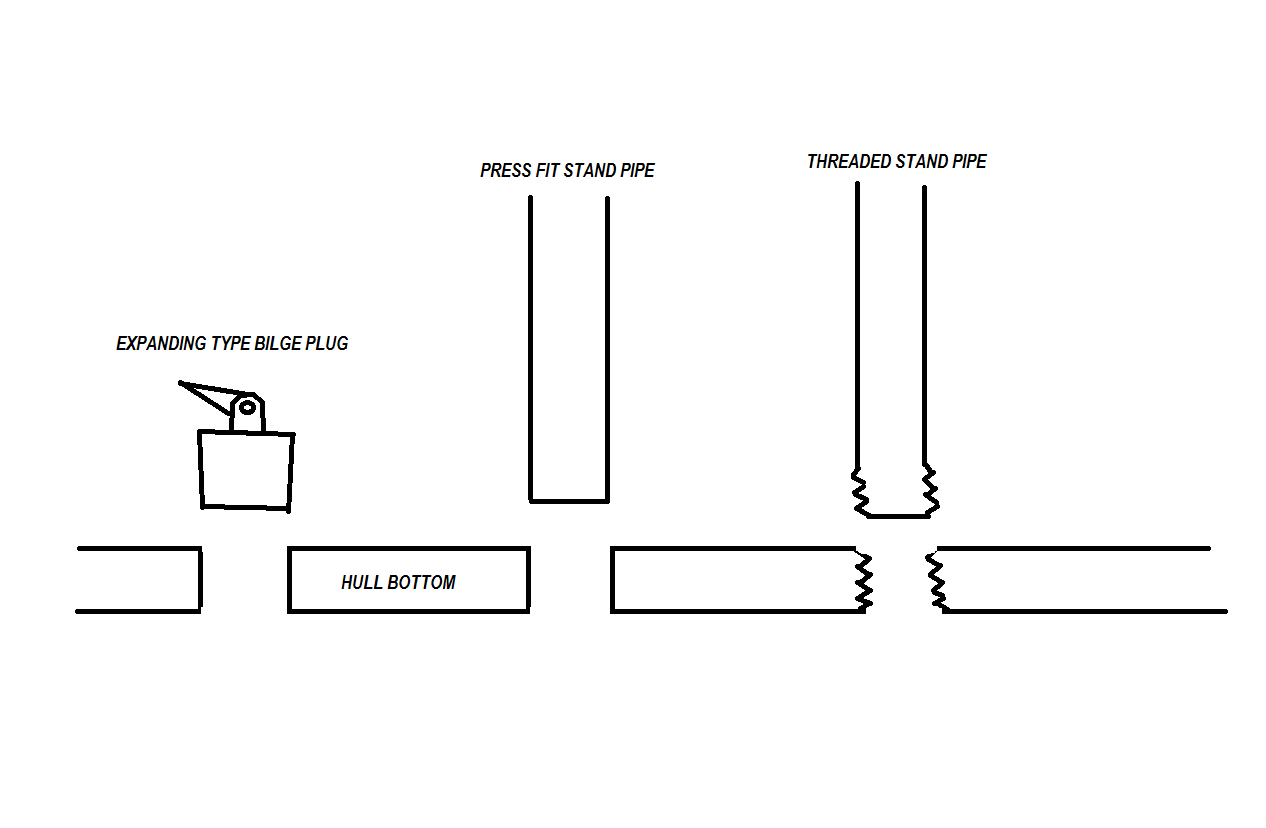

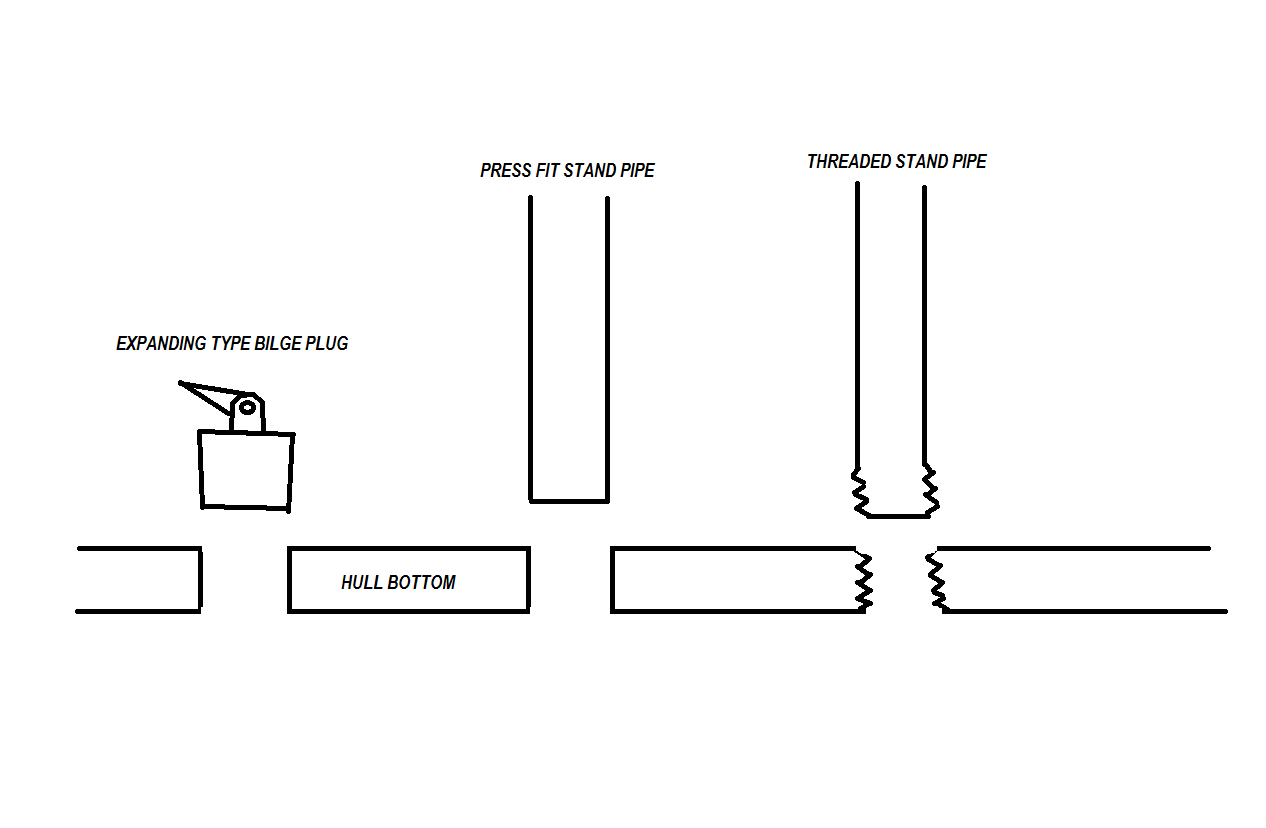

And finally, to be able to completely drain the live well after use, you would have to devise a way to eliminate the brass drain fitting and have threads that are flush with the bottom of the live well, where you could screw the drain/stand pipe directly into...that way when you remove it at the end of the day, the threaded opening would be at the lowest possible point in the well, allowing all the water to drain...

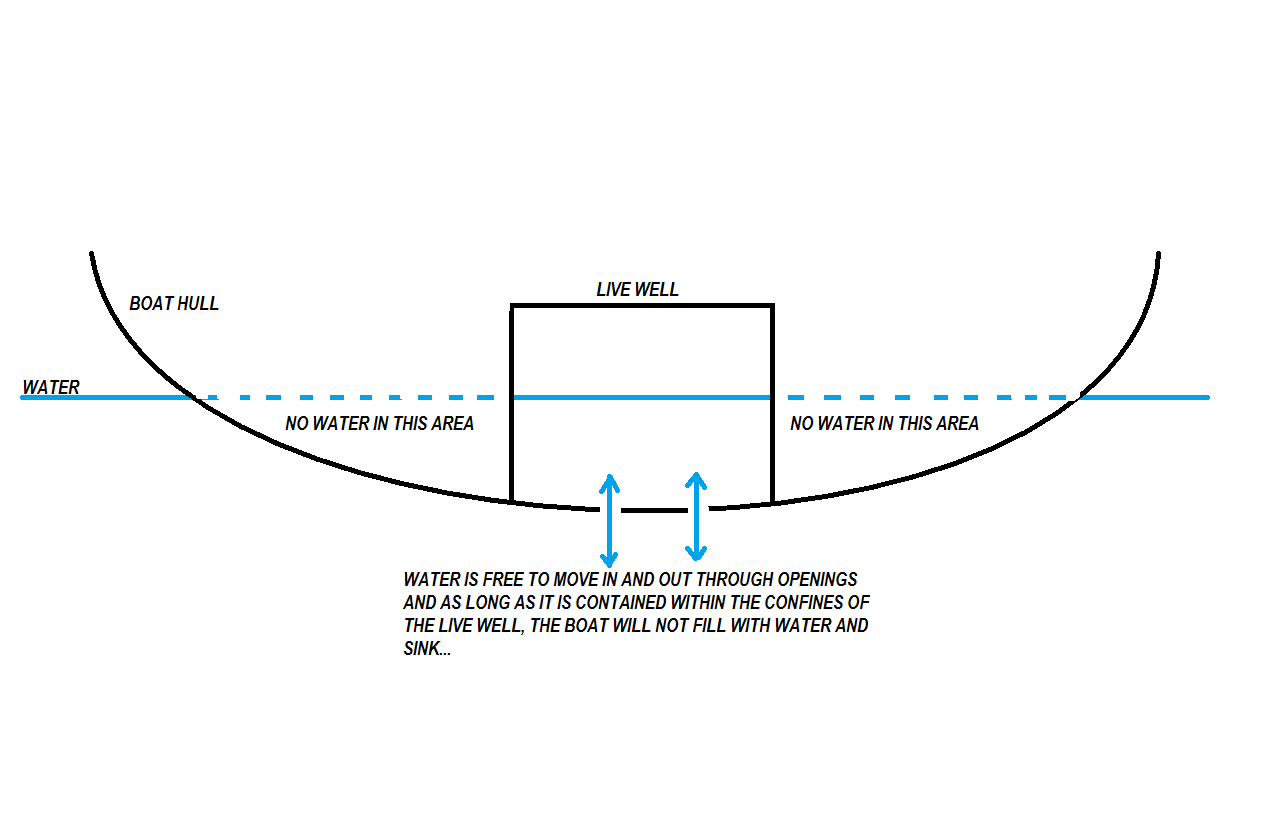

Another possibility would be to have a push in type stand pipe...even if it came loose...

would only allow enough water into the live well until it reached the same level as the body of water outside the boat...

see sketch...

OR...

OR...

Completely eliminate the stand pipe and use an expanding type rubber bilge plug in the drain hole...

The main disadvantage of this is that you would lose the ability to recirculate the water in the live well, which is the main purpose of the stand pipe when using a pump type system...

Below is a sketch of the three drain/stand pipe possibilities that eliminate the use of the brass thru-hull fitting...

Like I said, maybe a bit confusing...:facepalm: