Hope all of you Fathers had a great Fathers Day...I sure did!

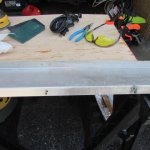

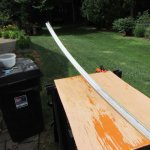

Decided not to strip paint today because I just didn't want the mess (and I was feeling a bit lazy). So this afternoon I thought I would give the new drill guide a tryout on those transom bolt holes that run vertically on the port and starboard sides of the aft aluminum transom sheet. Truth be told...I'm not really sure if I like the drill guide or not. Of the four drilled holes, two drilled out "wonky" using the drill guide and two drilled out nicely using a different drill bit and eyeballing the procedure. The drill chuck on the drill guide wobbles in place and allows for considerable run out at the tip of the drill bit. You can see the aluminum hole rip out in one of the photos with this post. I'll need to use the 3M 5200 in the bolt holes and perhaps some stainless washers between the transom plate and bolt nuts to seal the bolt hole exit point. Instead of continuing with the drill guide for the other two bolt locations I switched to my workshop set of Bullit drill bits by Black and Decker; these are great drill bits and very sharp. I did not use the drill guide, instead, eyeballed the drill bit entry from both sides of the wood transom using a small pilot hole sized drill (3/32" dia.) and then used a 1/4" diameter drill to drill out the final bolt hole through the wood transom. Worked out very nicely and the bolt actually threads easily through the bolt holes. Some 3M 5200 will work great to waterproof the bolt hole locations. Will see how it goes with the starboard side transom bolt holes tomorrow. Also, I found the 16 transom cap nails and they were in nice condition. Nailed four in place to hold the aluminum transom cap to the new wood transom. They must be stainless because they went into the oak transom without bending. So, after I get the starboard transom bolt holes drilled out and ready I'll wipe some 3M 5200 on the inside of the bolt holes with one of those small diameter wooden bamboo skewers, place some under the bolt head flange and where the bolt threads exit the drilled holes, place the washer (if used) and nut on the bolt and tighten them down and into place.

Safe boating,

Joe

Decided not to strip paint today because I just didn't want the mess (and I was feeling a bit lazy). So this afternoon I thought I would give the new drill guide a tryout on those transom bolt holes that run vertically on the port and starboard sides of the aft aluminum transom sheet. Truth be told...I'm not really sure if I like the drill guide or not. Of the four drilled holes, two drilled out "wonky" using the drill guide and two drilled out nicely using a different drill bit and eyeballing the procedure. The drill chuck on the drill guide wobbles in place and allows for considerable run out at the tip of the drill bit. You can see the aluminum hole rip out in one of the photos with this post. I'll need to use the 3M 5200 in the bolt holes and perhaps some stainless washers between the transom plate and bolt nuts to seal the bolt hole exit point. Instead of continuing with the drill guide for the other two bolt locations I switched to my workshop set of Bullit drill bits by Black and Decker; these are great drill bits and very sharp. I did not use the drill guide, instead, eyeballed the drill bit entry from both sides of the wood transom using a small pilot hole sized drill (3/32" dia.) and then used a 1/4" diameter drill to drill out the final bolt hole through the wood transom. Worked out very nicely and the bolt actually threads easily through the bolt holes. Some 3M 5200 will work great to waterproof the bolt hole locations. Will see how it goes with the starboard side transom bolt holes tomorrow. Also, I found the 16 transom cap nails and they were in nice condition. Nailed four in place to hold the aluminum transom cap to the new wood transom. They must be stainless because they went into the oak transom without bending. So, after I get the starboard transom bolt holes drilled out and ready I'll wipe some 3M 5200 on the inside of the bolt holes with one of those small diameter wooden bamboo skewers, place some under the bolt head flange and where the bolt threads exit the drilled holes, place the washer (if used) and nut on the bolt and tighten them down and into place.

Safe boating,

Joe