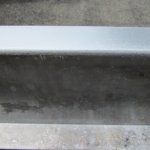

Finished up removing the paint from both aluminum channels that hold the upper rubber rub rails. Those things were nasty but they are clean now by golly! Lots of scratches and places on the channels that need a good sanding to smooth the exposed surfaces. Need to remove a few of the aluminum "stick out and grab the finger" things standing proud around the rivet holes, too! Tomorrow I will get at the lower rub rail channels and take paint off of those. No photos today...nothing exciting so thought you might like a break!

Safe boating,

Joe

Safe boating,

Joe