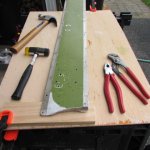

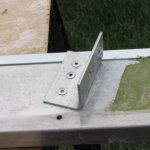

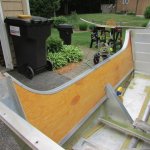

Finished mowing the yard today and then decided to strip some more paint off of the aluminum parts. And as I got everything ready to go it clouded up and started to rain...just enough to put a halt on that idea for the time being. Walked to the boat to pull the tarp over the transom and I noticed the two top gunwale pieces with the turned up ends. I had bent the aft ends upward and out of the way to get the original wood transom out of the boat. So, the sawhorses were pulled over to the front of the garage and placed under the eave overhang and I got a few tools out, placed one of the gunwale pieces on the table, thought about it for a moment and picked up the pliers. Taking my time I was able to walk the pliers across the bent up aluminum edge and gradually bend that turned up metal back down without creasing or putting a new rip in the aluminum. The hammers and a small metal block helped get the aft gunwale edge back into shape. The second gunwale piece had a small rip in the edge and I was able to get the metal back into form without lengthening that rip. I'll drill a small stop hole at the end of the rip and fill the area with JB Marine Weld, smooth it over, and the spot will be good to go. Another new experience for me that turned out better than I expected.

Safe boating,

Joe

I best try this when the Admiral is away and there are no children around...