Re: Wellcraft 170 Classic -89 full restoration

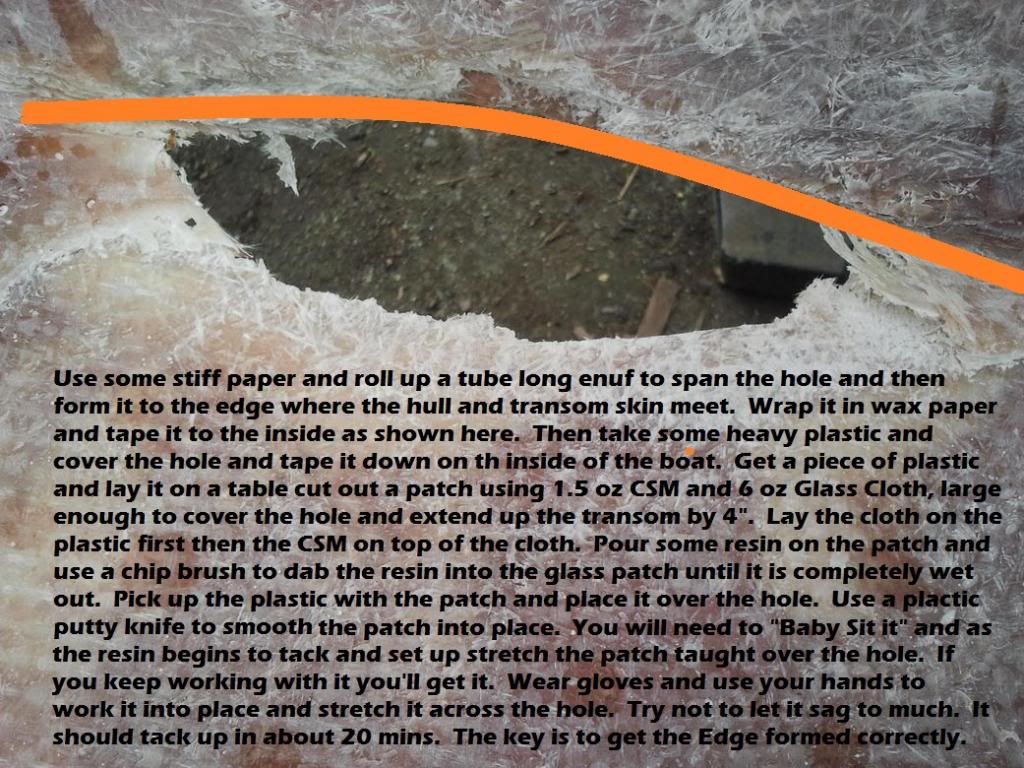

The hole was there when I bought the boat, I don' know what has happened... It had been patched but it was quite poorly done... So I opened it again.. I thought that now when the boat is completely bare it can be patched from the inside also.

The hole was there when I bought the boat, I don' know what has happened... It had been patched but it was quite poorly done... So I opened it again.. I thought that now when the boat is completely bare it can be patched from the inside also.