Hello,

First time poster, been lurking and learning for some time. Sorry for my first post being so long winded.

This fall we purchased our first boat ! It's a 1990 Larson 210 DC. I bought it from the second owner who bought it from the original owners and quickly realized he was over his head. The boat was listed as having a bad head gasket (4.3 V6), but I figured a crack and expected the engine to be junk. During inspection I found a few soft spots on the floor and fully expected rotted floors, stringers, bulkheads, etc. After purchase for basically what the Shorelander dual axle trailer was worth, I own it. Any visions of the wood being OK were quickly derailed during the 30 mile tow home. I've towed a ton of trailers and race cars in my life and this 3,000lb boat "felt" more like 5K lbs behind the truck. I knew it was water logged.

So, I dove in head first, tore everything out and getting ready to start the installation of new wood/glass. I have done a fair amount of glass work and I'm not too concerned about my ability especially after reading all the posts and advice on here. I do have a few questions and I'm sure many more will come as I progress. Please be patient as I'm unfamiliar with a lot of the terminology in the boating world.

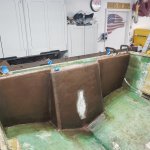

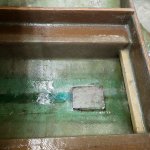

I expected the stringers and bulkheads to be rotten which they were, but I was hoping the transom was OK......a poke test at he bottom showed some rot, so I went ahead and tore it out too. Another reason to tear out the transom was I didn't like the way it was built. Trust me when I say I don't think I'm smarter than Larson, but I do fabricate entire racecars for fun, so I've seen a thing or two about strength etc. The transom consisted of a base layer of plywood laminated into the fiberglass with a second layer only partially as big as the first stapled to it. The two pieces were not even laminated together. This was in the "center" of the boat @ the keyhole and only about 2' wide. The second part of the rear of the boat stepped back and only had one 1/2" ply laminated to the glass with one 3/4" each side about 12"x8" stapled to the base ply to support the tie-down loops. Then in the top rear corners there is a section of the hull that sticks out about 8-10" (admittedly I have no idea what these are called or what their function is), these were just filled with rigid foam and a light coat of resin and chopped strand sprayed over them and a light gel coat.

So, here is my plan for the transom going back. Please feel free to jump in and advise me if I'm doing wrong. Thanks in advance, I'm sure I'll have lots of questions.

Oh, BTW I'm installing a 350 mag in place of the V-6.

Obviously start with 2, 3/4" pieces of plywood glued together and glassed to the center of the transom, following methods seen in these threads. (I'll be using poly resin, 1.5oz csm, and 1708 etc.) The "outer sections of the transom I will install one layer of 3/4" (up from factory 1/2") and extend it all the way to the hull at full height, covering the two kick outs at the top rear of each side. I will go back when foaming the floors and foam these two kick outs also. Then on each side of the transom there are two triangle shaped area's that the factory added no wood, it's just fiberglass. I would like to fill these areas with a 3/4" ply PB'd in , tabbed, and then laminate the entire transom with the last layer of 1708. I plan on making it as smooth as possible including the floors and gelcoating as I don't want carpet, or at the most snap-in carpet that we can remove and clean.

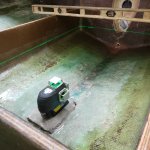

One question, you'll see the entire hull was spray-foamed with roughly 1" of foam and then some "apparently" sprayed fine chop and resin. I had to cut portions of this out be able to do the required tabbing. Was this foam there for strength, or noise reduction (both)? Do you think I should try and replicate this when done ?

On to the pics. I'll try and get more as I go, didn't get many pre-demo.

First time poster, been lurking and learning for some time. Sorry for my first post being so long winded.

This fall we purchased our first boat ! It's a 1990 Larson 210 DC. I bought it from the second owner who bought it from the original owners and quickly realized he was over his head. The boat was listed as having a bad head gasket (4.3 V6), but I figured a crack and expected the engine to be junk. During inspection I found a few soft spots on the floor and fully expected rotted floors, stringers, bulkheads, etc. After purchase for basically what the Shorelander dual axle trailer was worth, I own it. Any visions of the wood being OK were quickly derailed during the 30 mile tow home. I've towed a ton of trailers and race cars in my life and this 3,000lb boat "felt" more like 5K lbs behind the truck. I knew it was water logged.

So, I dove in head first, tore everything out and getting ready to start the installation of new wood/glass. I have done a fair amount of glass work and I'm not too concerned about my ability especially after reading all the posts and advice on here. I do have a few questions and I'm sure many more will come as I progress. Please be patient as I'm unfamiliar with a lot of the terminology in the boating world.

I expected the stringers and bulkheads to be rotten which they were, but I was hoping the transom was OK......a poke test at he bottom showed some rot, so I went ahead and tore it out too. Another reason to tear out the transom was I didn't like the way it was built. Trust me when I say I don't think I'm smarter than Larson, but I do fabricate entire racecars for fun, so I've seen a thing or two about strength etc. The transom consisted of a base layer of plywood laminated into the fiberglass with a second layer only partially as big as the first stapled to it. The two pieces were not even laminated together. This was in the "center" of the boat @ the keyhole and only about 2' wide. The second part of the rear of the boat stepped back and only had one 1/2" ply laminated to the glass with one 3/4" each side about 12"x8" stapled to the base ply to support the tie-down loops. Then in the top rear corners there is a section of the hull that sticks out about 8-10" (admittedly I have no idea what these are called or what their function is), these were just filled with rigid foam and a light coat of resin and chopped strand sprayed over them and a light gel coat.

So, here is my plan for the transom going back. Please feel free to jump in and advise me if I'm doing wrong. Thanks in advance, I'm sure I'll have lots of questions.

Oh, BTW I'm installing a 350 mag in place of the V-6.

Obviously start with 2, 3/4" pieces of plywood glued together and glassed to the center of the transom, following methods seen in these threads. (I'll be using poly resin, 1.5oz csm, and 1708 etc.) The "outer sections of the transom I will install one layer of 3/4" (up from factory 1/2") and extend it all the way to the hull at full height, covering the two kick outs at the top rear of each side. I will go back when foaming the floors and foam these two kick outs also. Then on each side of the transom there are two triangle shaped area's that the factory added no wood, it's just fiberglass. I would like to fill these areas with a 3/4" ply PB'd in , tabbed, and then laminate the entire transom with the last layer of 1708. I plan on making it as smooth as possible including the floors and gelcoating as I don't want carpet, or at the most snap-in carpet that we can remove and clean.

One question, you'll see the entire hull was spray-foamed with roughly 1" of foam and then some "apparently" sprayed fine chop and resin. I had to cut portions of this out be able to do the required tabbing. Was this foam there for strength, or noise reduction (both)? Do you think I should try and replicate this when done ?

On to the pics. I'll try and get more as I go, didn't get many pre-demo.