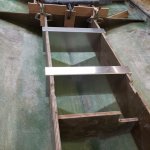

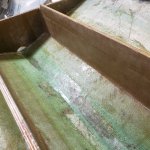

Looks good , this build is very similar to what I just did with a 1993 Larson SEI 180 , transom slightly different but was made the same with 1/2'' sheet stapled over 1'' larger area of the transom, i replace it with 2 x 3/4" for the whole area. As for what you call the shelves , since they are only holding in place with some chopped strand on top and one layer on spray foam with a bit more chop gun, i was inclined to think not structural. The only explanation I had was in my boat they were only there to provide a level bottom surface for the storage on the side. I had enough room underneath to tab in new floor but from the shelf to stern I had to cut and remove this layer of chop gun and spray foam to get proper tabbing to hull. If you check my last post

Larson SEI 180 Complete Rebuild | Boating Forum - iboats Boating Forums you can see how I covered it, not sure if it good or not but could not think of other solutions. As for the gas tank cover, to avoid screwing in the stringers, which are all covered with 6oz cloth and epoxy, I epoxied pieces of 1/2'' ply to stringers that I can screw into, if rot gets in them it will be isolated from structural members as long as they can hold those screws life is good. Boxing in that shelf may not be a great idea, it may change dynamics on how the hull flexes laterally, causing higher stress in an area not designed for it. Again just an opinion probably be fine but I would hate seeing the gel coat spidercrack at that exact location along the hull. Sorry I don't have many pictures posted can look for more if you need em.

Good luck