Well, ran into pic problems. my ip4 picswon't go into my xp...everyone knows that, right>>>...Another load of tech stuff. So I took out the camera with a camera card{remember them** and took some shots today then went to photobucket. Hope theses load.

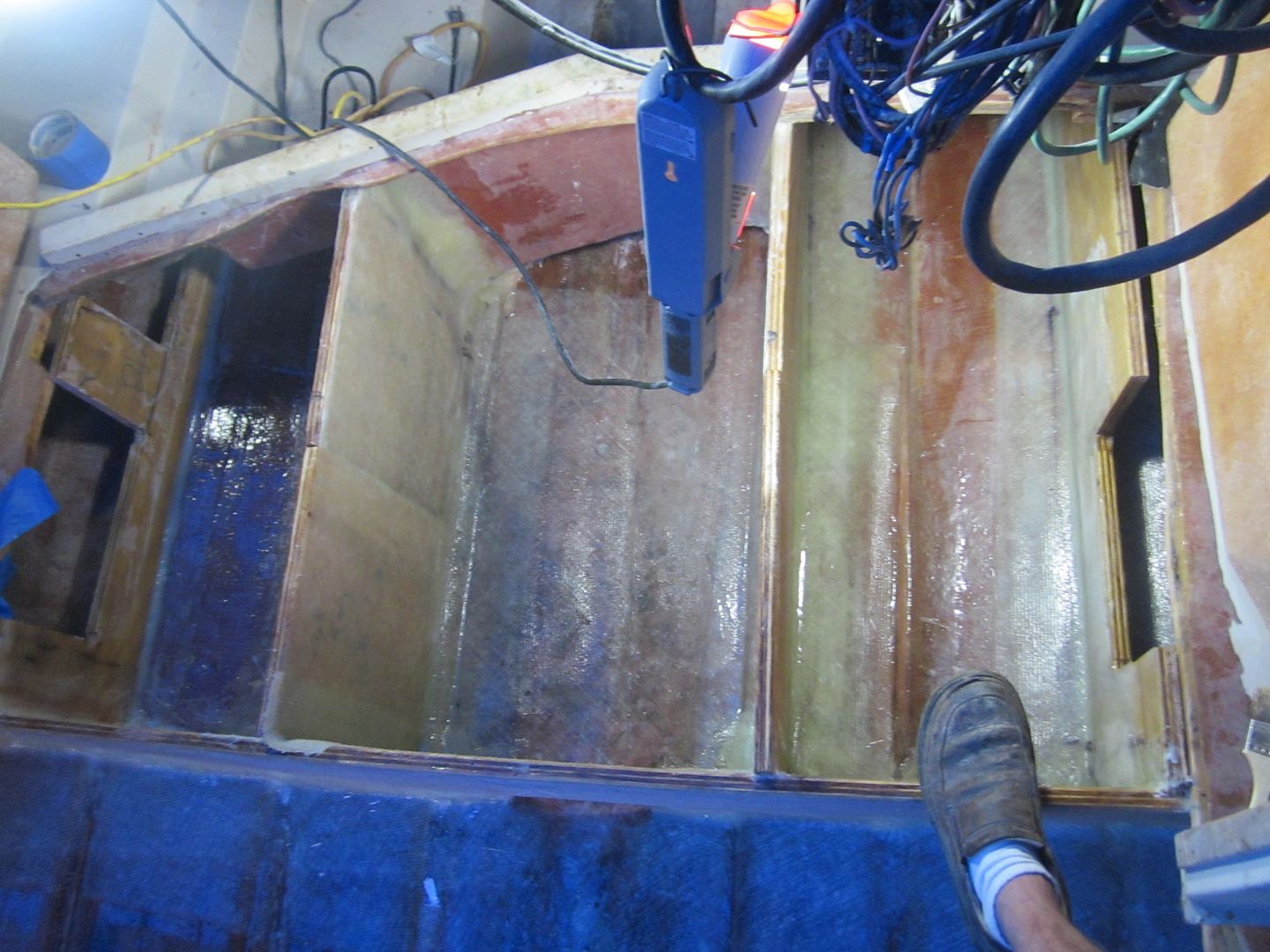

Primary work is up front under the cuddy. Tough spot. Two stringers furthest to left and right had to be cut open for me to access and be able to; fillet and glass.

left side

b

Then here is one of both sides. After that the next bulk head is for the gas tank area coming up soon. The center area above gets a well I saved. Two more stringers go in between the chopped up ones and the well area. Bulkheads are cut out but each area is in a sense a process so that I can later install bulkheads after all stringers are tabbed in and cleaned up.

I did use Wog's and Zool's ideas to hang up the sheets of glass but those pics are on my phone. Thanks for the ideas guys, it worked fine.

There will be 4 areas that need butt blocks after completion. left and right stringers where I made work access and the center two where the wood came up short to the main bulkhead. I think those need to be @ 6" both sides overlapping, then fillet and glassed again and of course pb.

The rear workshop;

More pics...I have to take my son out to the store...Then back into boat.;