Re: pic of work so far

OK here's a start of my part list, can anyone think of something else

LIST 1] Epox-6355564 one and a half gallons thin $59,00

2 ] Epx -p11 1-1 ratio pump set of two $ 5.95

3] 150 Thick Epoxy System Epox-150313 3/4 gal $31.50 Heres where I'am not sure was thinking,

4] fiberglass cloth 4oz x 50' [all three ten yards} $ 49.00

5] 8.5oz 2x2 twill fiberglass e cloth or 10oz eglass $ 68.50

6] Woven Roving 18oz x 50' $46.00

7] Liquid Urethane Pour Faom 2-16lb kit 59.00ea $118.00 total $377.95

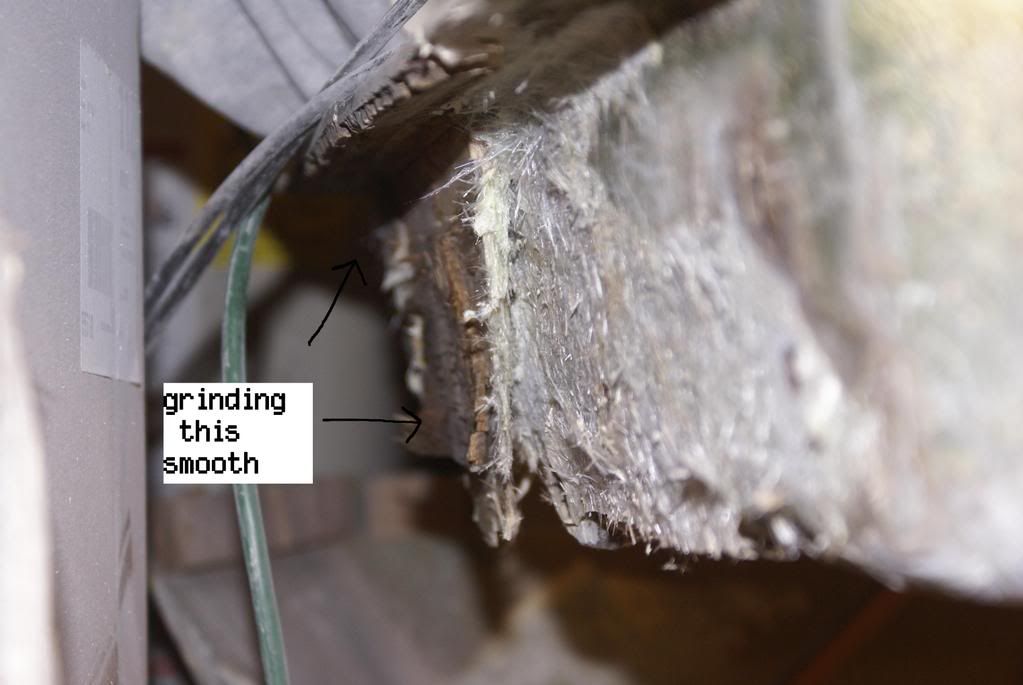

Well what do you guys think ?? am i going to have enought epoxy?? about 2 1/2 gal ?? Is this enought fiberglass, the two out side stringers are 3.5 tall and the center is 10 inchs tall , and the two out side stringers are 10 feet long and the center is 9 feet ... think I am going over board on the glass , the two out side stringers I can use one 10 foot piece and cut it in two , with it being 50 inchs wide , really only need it to be about 16 inchs in with, and thats with a 4inch layout on the hull on each side !!! the center has to be 22 inchs in with , I can allways use the extra on the deck , right !! man with the shipping it going to be over 500, Ok so I could use some input , Thanks John