Re: My tri-hull transom replacement w/ pics

So I figured out a way to keep the dust from getting all over everything in the shop.

It was expensive ($40) roll of plastic sheeting but the result is well worth it. I really hated having to spend a couple of hours dusting out the shop after every session of grinding.

I bought a gallon of epoxy resin and a ready made fairing mixture from U.S. I was not sure how well it would sand so I started the fairing before putting the cap back on.

At first I considered not fairing the inside of the hull. Originally the inside surfaces of the hull sides were left with allot of roving print through when the boat was built. In fact every inch of all of the inside of the hull were left rough. After getting the deck down and all of the work I put in to the seat boxes I could not leave well enough alone. I knew it would look funny having all those smooth newly glassed areas next to the rough factory surfaces.

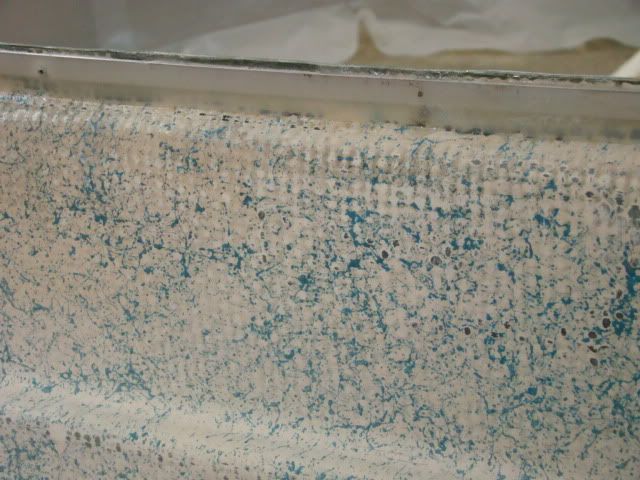

This is a pic of the inside of the hull. You can see how rough it is. Man! More Sanding!

Before starting any of the fairing I preped all of the areas to be faired by cleaning and sanding them. I paid close attention to the newly glassed areas so that sanding them would smooth them only slightly, keeping the glass strong and saving as much fairing compound as possible.

I mixed the compound in small batches using 1 quart plastic containers I picked up at Lowe's. After mixing a small amount of epoxy and hardener I mixed in the dry components until the mix turned a smooth mayo-like consistency. I then used a soft 4 inch plastic spreader (bondo spreader) to spread a thin layer of fairing compound over the surfaces I want smooth and flat.

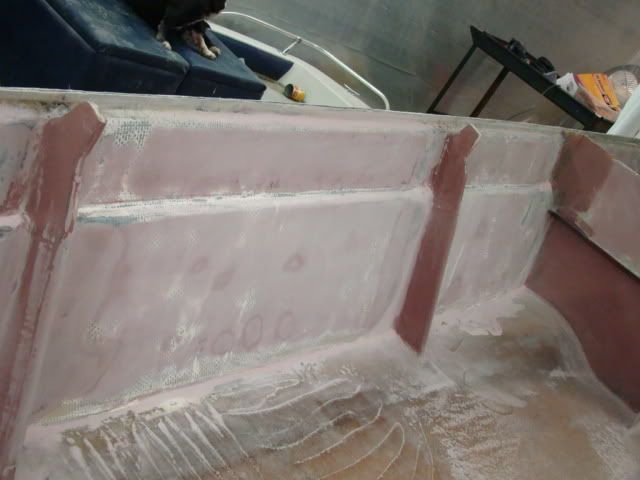

Here is an area on one of the seat boxes. After the compound has had time to harden. I worked to keep the compound as smooth as possible so getting it flat wont be such a chore.

I learned from fairing the deck on 'Nostalgic' that epoxy fairing compounds are difficult to sand. I was anxious to see if the ready made mix from U.S. would be any different. It is easier to sand, but it is best to sand it in its "sanding window". As the epoxy hardens it gets more difficult to sand. I found that it works best if you allow about 30 hours curing time before sanding it using the medium hardener.

Here is an area after a few minutes with the orbital sander and 40 grit paper. The light areas are flat and smooth, the darker areas are low and the areas where I sanded through are level.