The Force power

Commander

- Joined

- Feb 3, 2019

- Messages

- 2,359

Let me know, when you find the answer; I'd like to know as well

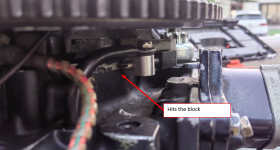

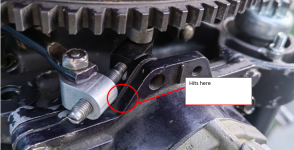

If it work? sure! its just harder to set/adjust the timing. (I would have the nut on the outside.)I saw some pictures in the internet from what seems same motor 1989 85HP Force, and this assembly looks to be installed backwards, the adjustment screw falls under the flywhee, (I had it like that before the rebuild but thought it was worng because some other pictures I have seen in the internet of other motors, and some schematics, also felt strange that the adjusting screw is not accesible in that possition:

This are internet pictures:

View attachment 397542

View attachment 397543

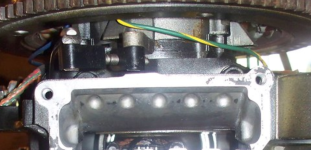

This is my motor when dissassembling for rebuild

View attachment 397544

Does it seem ok in that way?

thanks

Bad fuel pump membrane... It was new, maybe in the intallation I damaged it.Verify that all Cylinders are firing

Is it bogging down? check fuel-pump/membrane

ANY small pieces of metal found inside? I've seen the check-valves fall apart & pieces tearing the membraneBad fuel pump membrane... It was new, maybe in the intallation I damaged it.

The Idle is controlled by the timing tower you set by adjusting the screw-bolt & lock in position with the nutwhat should be the idle timing?

Didn't noticed any, actually the service I did to the pump previously was changing the check-valves so I got to them.ANY small pieces of metal found inside? I've seen the check-valves fall apart & pieces tearing the membrane

Hi gica,When you rebuilt the motor did you open all the covers? Like exhaust? Did you make sure the cover is not warped? My engine, a 120 was running like **** and dying at idle, had to run it at higher idle to stay in gear and not die. I was getting water in the cylinder chambers. But I was getting 4200RPM. I have twin 120s so it is easier if I run them together, if I ran just the one engine I could only get up to 10mph and it was bogging all the way.

This was after rebuild. The cover was way off at 0.020in in warping. I used a special stone and brought it back to straight at 0.002. I am wating for parts to get it back i the water.

You said you had leak from the head gasket, that's not good maybe the head is warped. Could be ok but these are small things that make a difference.

The carbs might also still be dirty. Recirculation also could hacve some dirt.

You did rebuild them and check the floats for right functionality. The screen at the fuel pump you didn't mention it was cleaned. Hose clamped etc. Most of these don't matter in the big picture but 1200RPM and that's it is not good. Mine is at 4400 and I also bought 2 new props from 19 down to 15 to get the 5200 or so hopefully. The timing is at wot with engine off cranking timing 28BTDC. Measure the stator and trigger as per CDI electronics guides. It is weird that you don't get more RPM. I mean can't you test at home in a small plastic tank and see if you get more RPM when you adjust the idle screw in. It should give you more than 1200 at idle.

I think you can remove the gear engaging cable and try to put it in your tank at idle and accelerate without going in gear briefly to see if it goes up in RPM. I had the same issue in the parking hose it ran great in the lake it would die in gear unless I set RPM screw at max. Went there3 or 4 times. It is pretty annoying.Hi gica,

I didn't open exhaust or intake covers didn't wanted to mess with it, in muff or tank I can get 1600 RPMs in neutral not in gear just idle acceleration, I didnt try with gear on because my tank is to small and all water be gone and muffs I believe is no good to do it. I missed some basic stuff in the pump I will be focusing on it, one hose comming from the block in the bottom I belive is suction was not clamped and the hose looks cracked, might be leaking, the screen in the filter was little bit dirty not too much but I now cleaned it, as mentioned in previous post the membrane was and old reused that feels hard brittle and was slightly cracked, I think it cracked because of the brittleness because I didn't noticed before, lastly when I suck through the filter in I can get some air so I think the check valve or seal there is not working properly. I will focus in detail in the pump at this time, I just wish I could try it at home and not having to go to the lake thatt is 1.5 hrs from here to find out, do you have any suggestions for that? .

Thanks for the input

Thanks, maybe I didnt explained myself very well, I can pull the throttle lever to accelerate without engaging the gears, this is I guess a function for cold starts, in that way I can accelerate up to 1600 RPM's that is the maximum it allows me to do with this function, everything looks good there with the hose or tank, very different in the lake. Now also I don't know how important is but my home is 4900 feet above sea level and the lake I use to go is roughly 1500, I usually have more issues starting it in the lake than at home, settings should be different I guess for this different altitudes.I think you can remove the gear engaging cable and try to put it in your tank at idle and accelerate without going in gear briefly to see if it goes up in RPM. I had the same issue in the parking hose it ran great in the lake it would die in gear unless I set RPM screw at max. Went there3 or 4 times. It is pretty annoying.

And then I founf the water in number 4 on the piston.Ipened up exhaust and there was milky residue on 3 and 4. I had to resurface the exhUst cover, I got new gaskets and a separation plate, and I got another head just in case. I hope that ot will seal the area andnothave any leaks.

But I was getting 4200 RPM in gear but only withy twin engine on, without it was a mess. Since you only have one engine it is different. But remove the shif cable and keave the throttle and see if it accelerates passed 1600 briefly and clean. You shouldn't cause any harm with short bursts. I am.surprisedyou don't have a bipassbutton at the remote to pushin andonly use the remote to warm it up without engaging. My friend's 96 force has that. I don't because mine is a twin engine