the roller on your trailer,is there a certain height setting on those,mine doesn't set quite that high as yours,and I don't even know if my boat touches it when i put her back on,haven't got to that stage yet,just curious,

Best guess is that as long as it sits slightly above the frame of the trailer, the purpose of the roller is to begin guiding the bow/keel up till the bunks take over to carry the weight...

O.K. finally Friday!

Er ah, Saturday...yeah, that's it...

And I have almost enough stuff to actually attempt at making some progress...

Except time...:facepalm:

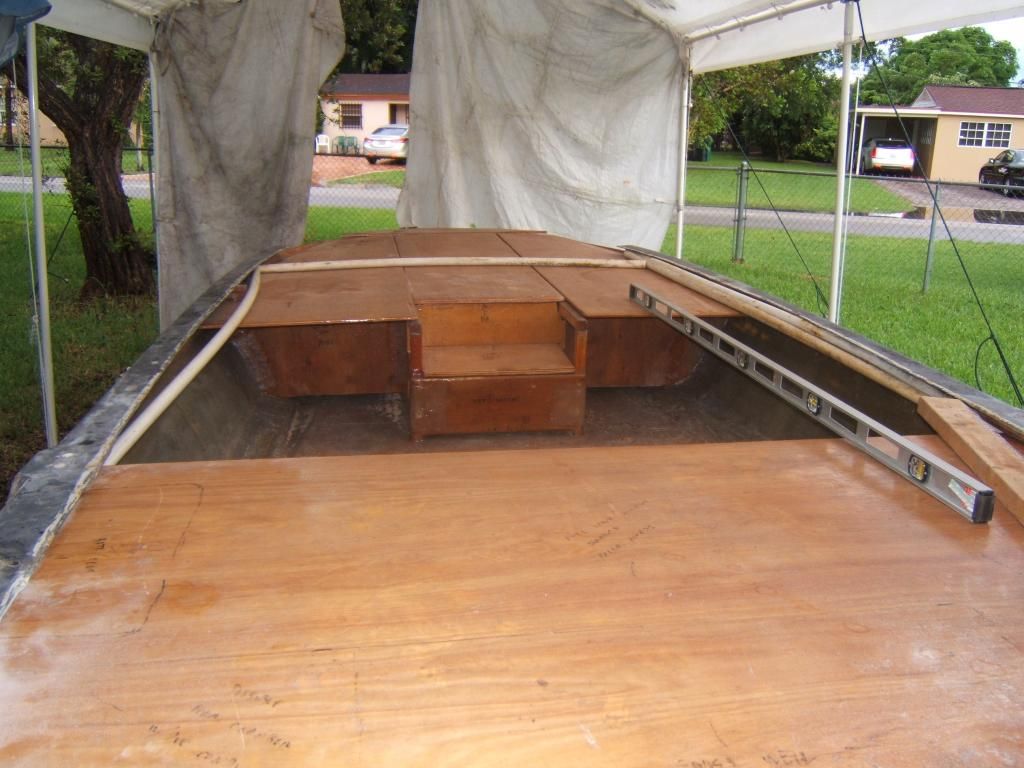

Needed a new D/A, electric, to sand, ruff-n-scuff and generally prep the

ENTIRE interior of the hull in anticipation for some serious finishing steps and actual forward progress...

Ordered a new DeWalt at a great price thru Amazon a couple of days ago and it arrived today...almost seems as though they are using drones to deliver these packages, they get here so fast...

Modified some vacuum hoses in order to be able to connect the shop vac to it...

The sections of PVC pipe you see in the previous pics are mainly being used as study guides to get an idea of where, what size and how many

"conduits" I want/need to run down the sides of the gunwales...

They will be used as places to run both control cables and wiring...

One of the reasons this "finishing" stage is taking so long, is due to my hard headed approach to creating a custom cap for my boat...

As originally designed, it would have probably worked out fine...but compared to the much more efficient use of space in today's modern bass boats...I just had to come up with my own way of designing the interior to better suit my needs and wants...

Yes, it has, and will extend, the build time of this boat by quite a bit, but in the end I will end up with a layout I am happy with along with having learned a ton.

Another side benefit will be that I get to use, document and hopefully share some of the techniques I have used in the past to custom build parts for my own use...

Some of the things I will be doing include building two custom consoles, custom seating area, custom live wells, adding as much floatation foam as possible to any cavities that I will be creating as I get closer to figuring out how I am going to make the interior...

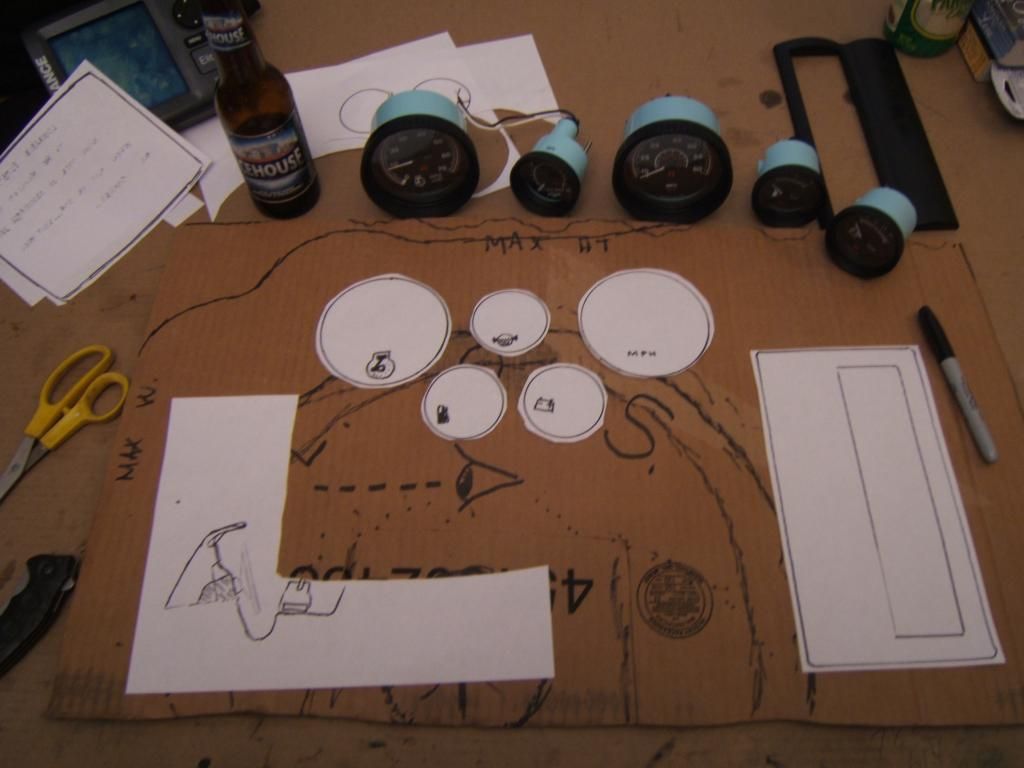

The following pics are merely a beginning of some of the ideas I will be working on and begin the process of creating actual forms and molds to bring my vision to reality...

MIstakes can and will be made, but that is part of the learning curve...

Excessive boo-boos can be minimized by doing all of the engineering in cheap cardboard and tape, and if you want, hot glue...

Here are a couple of "studies" in cardboard, masking tape and sections of PVC pipe, all mocked up to help me visualize and "flesh" out the Helm station...

Here is a "TEST" bend on some Sch.40 PVC pipe...warmed it slowly with a small propane torch until it just started to bend, then keep moving the heat, all around and forward in the direction you want the bend to go...

That's all for now...hopefully I'll get some more time on this in the next few days...

Happy Saturday, y'all!