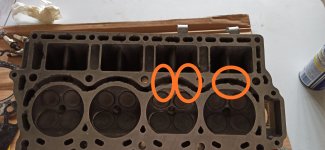

You're correct, the leak is NOT the exhaust valve itself. However when I piur water into the exhaust port, water was trickling out. When I piur water into the intake hole, it held fine. But... After removing the intake valve, I find the hole. Question now is how the heck that happened??? But I'm now certain this is the reason why cylinder 4 was not doing it's thing.While possible, unless the leak is right next to the valve I would not think the source is the exhaust valve. But repeat the test on the intake side. If you have an intake that is leaking the same way, then that is almost surely a source, though maybe not the only one.

Ahick, Matt Fl, if this hole is patched well, can I get a reconsideration that this will fix my issue.