Re: Formula 330SS Bulkhead Replacement

I did some more work on the boat today - President's Day . . .

The snow on Cape Cod was fairly heavy and some had accumulated on the tarp.

However, the tarp and frame held up, so I was able to clear it off.

I lowered the tank from the boat . . . gravity did a pretty good job and the snow made for a soft landing.

I set the tank up on a couple of saw horses and drained off the residual fuel, the best I could.

There were a dozen (or so) pitted areas along the belly of the tank. The depth to 'clean metal' was about 1 mm, maybe 1.5 mm at the worst case. The tank itself is 5 mm thick (0.190"), so generally the pits are 20-30% of the thickness. Once the depth of the pits approach 50%, then it is time to consider a new tank or welding repair. (IMHO)

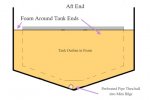

I removed the remaining foam, mostly stuck to the forward face of the tank, and then gave the tank a sanding. I will probably have to use some paint remover to get down to bare metal in all areas of the tank.

Then, I took a look in the fuel bay and started to remove the foam.. Since it was only about 20 degrees F outside, much of the saturated foam towards the rear of the fuel bay was frozen. So, I worked on the forward area and exposed the forward bulkhead. The forward bulkhead had moisture beginning to penetrate from the middle. So, I will want to apply some corrective measures to this bulkhead as well. I could treat it with EG or perhaps replace it, same as the rear bulkhead.

I'll have to give it some thought . . . my inclination is to get it to dry out (since it has a fair amount of bare wood surface), then treat it with EG. . . allow it to absorb/dry out, then glass over it. Anyway, if I get a big enough piece of plywood, then I could replace both bulkheads.

So, as these sorts of projects unfold, this is now the second 'surprise' that I have encountered. The project started out with the intention of replacing the firewall bulkhead . . . quickly expanded to re-installing the fuel tank . . . and now potentially replacing the forward bulkhead. No more surprises would be good.

Here is a video of the day as well:

It will be a couple of weeks until I can do some more work on the boat. Hopefully the weather will start to let up, making things a bit easier.