- Joined

- Jul 18, 2011

- Messages

- 18,958

Re: Formula 330SS Bulkhead Replacement

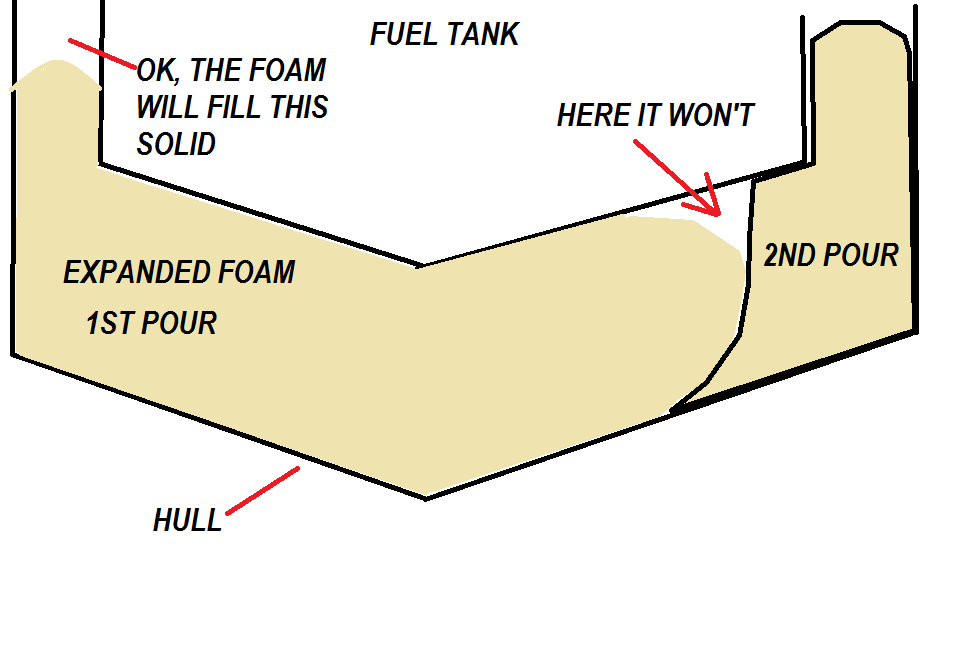

Yea, Option #2 may be the way to go . . . I can just see if I tried to lower the tank into the expanding foam (a La Option #1), I may not get it set properly and have a heck of a mess on my hands

Formula uses the hose in the foam 'trick' for the fuel tanks as well as the water tanks to feed the foam into the base of the fuel tank bay. I pointed out one of the hoses in one of my videos. Kind of a neat trick. I would think that they use some amount of pressure to quickly move the foam through the hose.

My rough calculations indicate that I might need upwards of 16 cubic feet of foam to secure the tank. I may plan on 20 cubic feet, just to make sure there is more than enough material. I think that would be 8-10 total gallons of the 2-part stuff at 4 lbs/cubic foot density. I'd have to rig something up to dispense and mix that amount liquid fairly quickly :noidea:

I would lean toward option two. Replaced my 27 gallon water tank and secured the top with wood braces before I sprayed in the foam. The amount of force which will be pushing up on the bottom of the tank will increase as the foam dries. It would be terrible if the tank was pushed up to far where you would have to remove it again to drop it down. Now I'm sure you would have some time before the pressure when be difficult to over come to set the tank back in, but that amount of time is unknown.

My original water tank had remnants of tubes which went to the bottom of the tank and those tubes were used to release the foam under the tank and have it come up. Once sprayed in the tubes were left and cut off flush.

Yea, Option #2 may be the way to go . . . I can just see if I tried to lower the tank into the expanding foam (a La Option #1), I may not get it set properly and have a heck of a mess on my hands

Formula uses the hose in the foam 'trick' for the fuel tanks as well as the water tanks to feed the foam into the base of the fuel tank bay. I pointed out one of the hoses in one of my videos. Kind of a neat trick. I would think that they use some amount of pressure to quickly move the foam through the hose.

My rough calculations indicate that I might need upwards of 16 cubic feet of foam to secure the tank. I may plan on 20 cubic feet, just to make sure there is more than enough material. I think that would be 8-10 total gallons of the 2-part stuff at 4 lbs/cubic foot density. I'd have to rig something up to dispense and mix that amount liquid fairly quickly :noidea:

Last edited: