A very interesting thread, especially considering I spent years with the USCG testing boats for flotation, and now I am restoring a 1972 Sea Ray, which means I am removing a lot of saturated foam. I also participated in a USCG sponsored research project in 2005 to determine why foam that is not supposed to absorb water, does.

Some history. Two part polyurethane "pour", "spray", "Injection" foam, is supposed to be closed cell, meaning no water absorption. So if it is absorbing water then it is not closed cell. When I first ran the test program back in the mid 80's most of the foam was made to a different formula than the foam used now, and the blowing agents (the stuff that makes it foam) were HCFCs. As most of you probably know the EPA severely limited use of HCFCs in the early 90's because the deplete the ozone layer in the atmosphere. So the foam manufacturers changed the blowing agents and the formulas for the foam. So where is this leading?

Before 1995 we used to see an occasional boat with water absorption, after 1995 it became epidemic. The foam in your boat is supposed to provide adequate flotation up to ten years (that's the law) Prior to 2000 it was 5 years. But now we see new boats with problems.

Several research projects have been done to find out why. The results have been inconclusive. But from almost 30 years of experience here is what I think is happening.

First: Pour foam is sensitive to temperature, humidity, mixing ratios and dirt. In boat factories it is almost always sprayed into a boat using a gun similar to a paint spray gun. The gun has to be calibrated for the right mix ratios and kept clean. This is usually done at the beginning of the day. Twice a day would be better. Also most builders shoot some into a paper bag or cardboard box to test the setup. If it foams they think everything is ok. This may not be so. This is what chemists call an exothermic reaction, that is it generates heat which contributes to the reaction. Too much heat and it foams too fast and breaks all the cells, so you get something that looks like foam on the outside, but if you cut into you see what looks like broken glass. Too little heat and it doesn't foam right and you get what look like cowpies and has the consistency of bread dough. Unfortunately many manufacturers buy this stuff in quantity in 55 gallon drums and store it outside or in an unheated shed or storeroom. They should bring the stuff inside and let it warm to room temperature. But even so in some northern states room temperature is 50 -55 degrees. So the stuff may be too cold. One manufacturer had to recall thousands of boats because of this.

Conversely in southern climes it may be way to warm. Plus that it is supposed to be used in a certain humidity range. In southern climes the humidity may be off the charts.

All of this affects what comes out of the gun and goes into the boat.

On top of that polyurethane is supposedly not affected by gasoline, bilge cleaners, oils etc. But some of the stuff I took out of my boat had been exposed to gasoline and it was black and brittle (But it was forty years old and proably 80% is just fine). So other things in your boat may have affected the foam.

Also boats sit outside most of the time including the winter and go through freeze and thaw cyles that affect the foam. If the foam already has water in it and it freezes and then thaws it does serious damage to the cells. Also it has been mentioned that if the boat fills with water and sits that way for long periods, it certainly isn't good for the foam.

Many years ago the USCG also did a research project on water absorption (I was the project officer) on machine made foam (board, block, or stick foam) Guess what? It had None! of these problems. The problem is, it is hard for the average boat owner to get polyurethane board foam. Construction companies use it, but it is not generally sold to the public. However Polystyrene foam is sold everywhere as insulating foam, in boards usually 2' X 8' by 2 in. It comes in various colors too, White, pink, blue.

The problem with Polystyrene (styrofoam) is it is dissolved by gasoline, oils, cleaners, etc. So if you use it, you have to protect it from this chemicals.

Of course boat manufacturers could do a better job of designing the boat for adequate drainage, or encasing the foam in fiberglass or putting it in a plastic envelope (a bag). There is manufacturer in Australia who has used bagging with great success. There are some US manufacturers who use styrofoam in sealed boxes and that works well too.

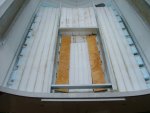

My recommendation for many years has been used board foam, and seal it up. That is what I am going to do. Also put in limber holes to drain the hull. Even if you cover your boat, and never swamp it, some water still gets in and needs to be drained away.