ripazka

Petty Officer 1st Class

- Joined

- Jul 30, 2016

- Messages

- 246

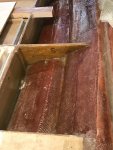

Chuck, what was your plan on top of the gas tank? Previously I had that sheet completely separated from the deck and I could lift it up. It was kind of great but I think it also increases water intrusion risk so I will not do it now. Are you going to make some kind of "maintenance hatch"? I thought Im going to install water proof hatches on it...