PC on the Bayou

Petty Officer 1st Class

- Joined

- Apr 27, 2020

- Messages

- 234

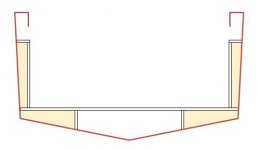

If I'm reading your response correctly, if I go with the diagram & also put some screws through the stringer into the cleats I should be solid and well encapsulated.All the above you just asked is the correct method.

Thanks for the input.