I put together a "tent" to cover the boat while I continue to work fiberglassing and installation. Sorry no pictures yet, but I'll give you more soon (it's a mess in the boat/tent right now). A 1500 watt space heater plus my lights are giving me plenty of warmth. It was up to 75-80 degrees in there while it was in the 40's & 50's outside. I'm confident that I can keep going through our south Louisiana winter if necessary.

I put in my forward bulkhead (anchor locker) in the bow and PB'd in the fuel tank & ski locker subfloors, and glassed the underside of my deck wood. I also cut out some additional wood and the cleats to add onto the stringers so that I can install my deck.

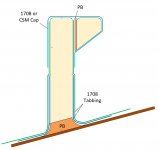

I am planning to use PB on the cleats to "glue" them to the stringers. Do most of you, also, screw them to the stringers or will the PB be enough to be solid if I clamp them good until the PB fully sets? Also, do you usually do more than put a coat of resin on the cleats (i.e., actually cover them with CSM)?

I was, also, thinking about including a "cap" of CSM over the stringer and cleat to encapsulate the entire thing rather than capping the stringer and then attaching the cleat. Would the 1708 and PB be enough to isolate the cleat from the stringer or should I cap the stringer first and not worry about capping / encapsulating the cleat?

View attachment 330086