Rick Stephens

Admiral

- Joined

- Aug 13, 2013

- Messages

- 6,118

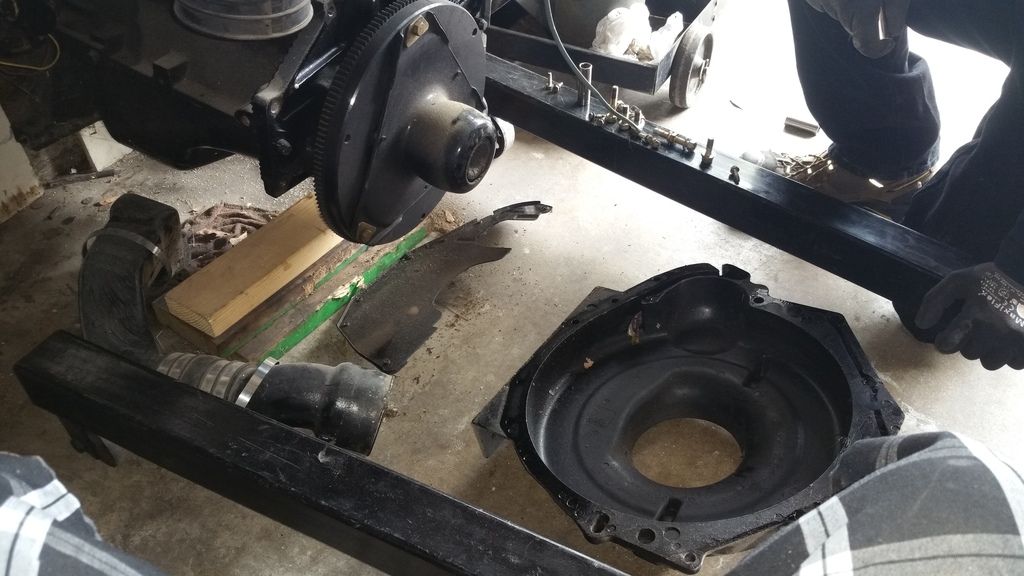

I just did my transom install. I used Coppercoat, just a fancy rubber cement, and glued the big seal into the gimbal housing. Then I used 4200 on the outside 1/2 inch of the bottom aluminum carriage bolts. All the rest of the bolts just got greased up with 2-4-C and nothing else.

I don't like that there is just that little teensy rubber washer for that carriage bolt. And the ones I pulled out were corroded really bad. Hence I sealed the outer 1/2 inch. Mercruiser puts em in dry.

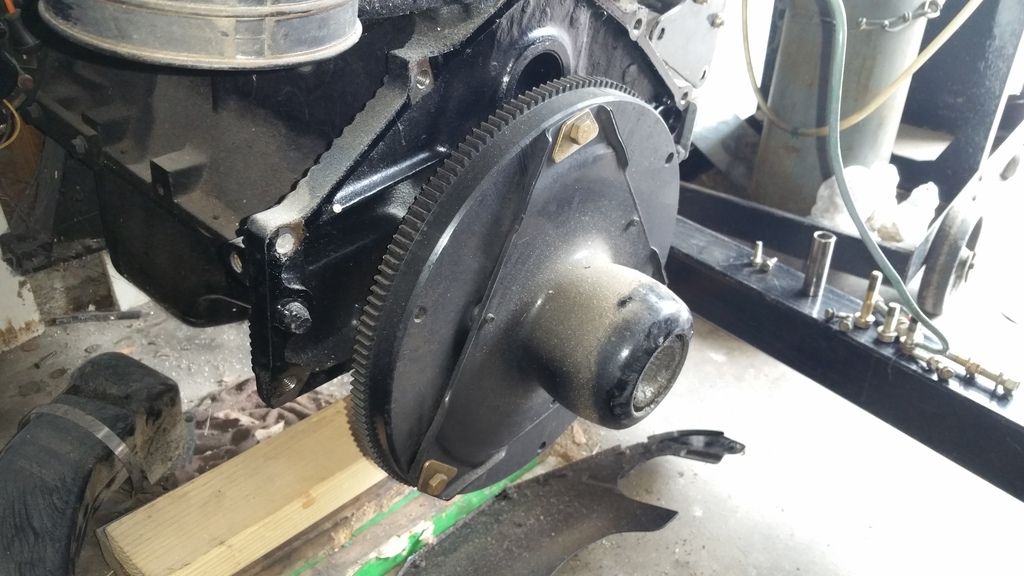

I built brand new motor mounts since I am going from a 4 cylinder to a 6 cylinder. So I know just what you mean about motor mounts being right. When you get your transom plate installed, take a 6 foot string and run it up through both motor mount holes across underneath. Then cross them so the loose ends go to opposite motor mount. If the mounts are equal height, the strings will just touch in the center where they cross.

On overall height, well, it is always better to be low than too high. That always sucks.

Got my fingers crossed for you.

Rick

I don't like that there is just that little teensy rubber washer for that carriage bolt. And the ones I pulled out were corroded really bad. Hence I sealed the outer 1/2 inch. Mercruiser puts em in dry.

I built brand new motor mounts since I am going from a 4 cylinder to a 6 cylinder. So I know just what you mean about motor mounts being right. When you get your transom plate installed, take a 6 foot string and run it up through both motor mount holes across underneath. Then cross them so the loose ends go to opposite motor mount. If the mounts are equal height, the strings will just touch in the center where they cross.

On overall height, well, it is always better to be low than too high. That always sucks.

Got my fingers crossed for you.

Rick

Last edited: