Mark72233

Ensign

- Joined

- Jul 11, 2014

- Messages

- 926

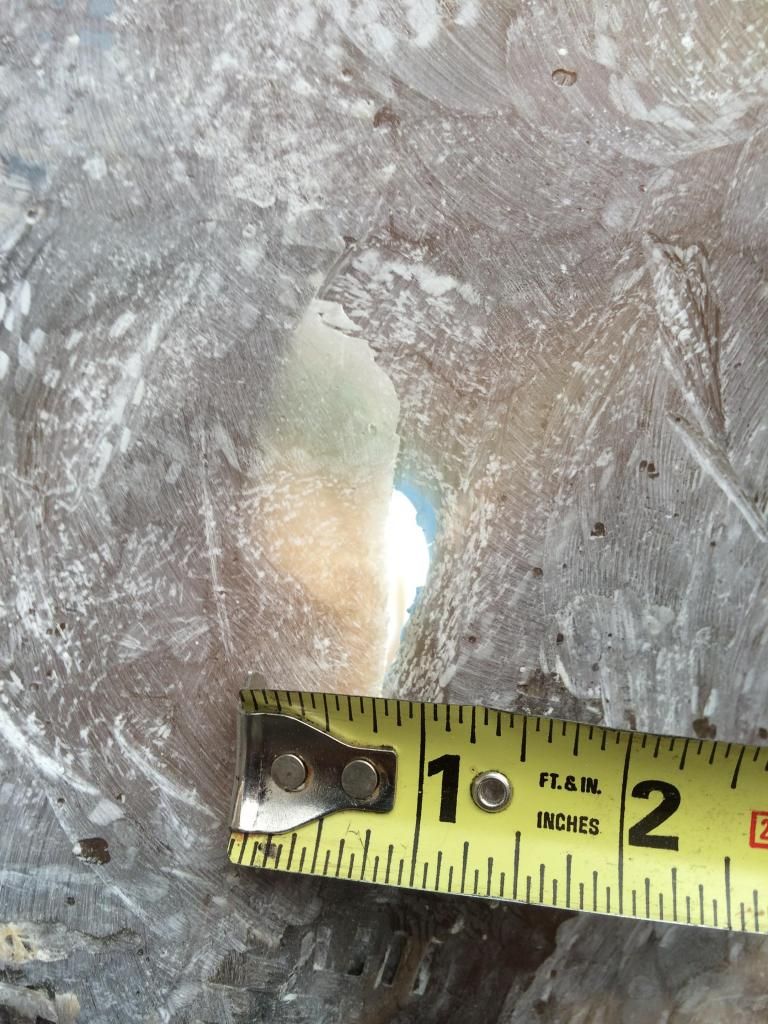

I have a question on some of the hull repairs before I do them. One is a small hole in the bottom of the hull where a thru hull transducer was removed. On the outside of the hull I was going to tape it closed. Inside after grinding and cleaning with Acetone should I put 5200 or P.B. in the hole. Then should I put a couple of layers of 1708 over it.